mogsrus

New member

- 3

- 0

- 0

- Location

- Prescott Arizona

Hello Bob

I am new to this forum and have a Agricultural version of the 406 Unimog which I just fitted a FL-4 loader off an SEE.

You mentioned that you have done that as well and I wonder about the hydraulic connections on yours and how the loader works for you.

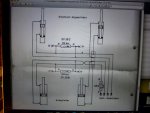

My cylinders were leaking and after rebuilding the cylinders for the bucket function I cannot get the bucket to "curl" back any more.

The entire unit seems to be acting a little weird, meaning that the bucket function seems to influence the lift function.

Is there anything you could share with me in about this, possibly some photos.

I speak fluent German and still have contacts over there in case you need any assistance.

The Schmidt website shows all the parts etc.but the US has changed a few things such as mounting brackets, called "Anbau Konsolen".

My 406 has all sorts of attachments and sadly I had to remove my Schmidt Quick attachment plate for the SEE FL-4 loader because, unlike the German version, it cannot be used together which is sad.

Besides all the frame reinforcements and stronger front coil springs on the front of the SEE there are also some more very important details for using the FL-4 loader on a civilian 406.

It is supposed to have an entire sub frame support mounted under the chassis so the frame does not break under laod and stays flexible for off road use. Very elaborate set up and I have never actually seen one installed. Please let me know if you could help me figure out what's going on with my bucket function.

Best Regards

Thilo Kass / Prescott AZ / www.mogsrus.com / www.prescottbackcountry.com

I am new to this forum and have a Agricultural version of the 406 Unimog which I just fitted a FL-4 loader off an SEE.

You mentioned that you have done that as well and I wonder about the hydraulic connections on yours and how the loader works for you.

My cylinders were leaking and after rebuilding the cylinders for the bucket function I cannot get the bucket to "curl" back any more.

The entire unit seems to be acting a little weird, meaning that the bucket function seems to influence the lift function.

Is there anything you could share with me in about this, possibly some photos.

I speak fluent German and still have contacts over there in case you need any assistance.

The Schmidt website shows all the parts etc.but the US has changed a few things such as mounting brackets, called "Anbau Konsolen".

My 406 has all sorts of attachments and sadly I had to remove my Schmidt Quick attachment plate for the SEE FL-4 loader because, unlike the German version, it cannot be used together which is sad.

Besides all the frame reinforcements and stronger front coil springs on the front of the SEE there are also some more very important details for using the FL-4 loader on a civilian 406.

It is supposed to have an entire sub frame support mounted under the chassis so the frame does not break under laod and stays flexible for off road use. Very elaborate set up and I have never actually seen one installed. Please let me know if you could help me figure out what's going on with my bucket function.

Best Regards

Thilo Kass / Prescott AZ / www.mogsrus.com / www.prescottbackcountry.com

![DSCN1532[1].jpg DSCN1532[1].jpg](https://www.steelsoldiers.com/data/attachments/449/449795-6f406a7e63dc367a85cd9ade39aded66.jpg)

![DSCN1538[1].jpg DSCN1538[1].jpg](https://www.steelsoldiers.com/data/attachments/449/449914-e62d7edaba70e88daa5d310e69223168.jpg)