I busted a gut literally removing a Pontiac GTO flywheel 20 years ago. But the Craftsman socket cracked first. The second one held. Sears replaced it, but the guy did ask how I managed to break it and was skeptical about a 24" snap-on rachet. He didn't argue about replacing it, just was skeptical that one person on the end of a long rachet could breal that. The socket may have been defective, I suppose. I am glad you got them out, 1000FT Lb is huge torque!

Mr. Bjorn, sir..

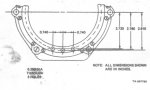

Do I see by the picture that the rear main seal is the shiny new aluminum looking thing, and that it can be replaced "easily", when a clutch job is done? (assuming one removes the flywheel)

And I saw your article on grounding in the mag. That is a great article there. I bet alot of people overlook the special little washers.