JRBAMATEX

New member

- 144

- 1

- 0

- Location

- Haslet, TX

Friday I used the deuce to actually do some work. Drove it about 80 miles round trip to acquire some flagstone for around the house. Why go 80 Miles for flagstone?..... Cause it was free and gave me a great excuse to work/drive the deuce. Also that much flagstone would have squashed my pickup.

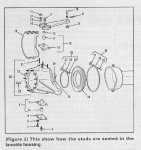

When I was backing the truck into the drive to pick up the stone I heard a strange kind of pop or cracking noise from the front right portion of the truck. I have been looking at the right front tire and it has looked as though it was leaning out from the top ever so slightly. Now I see some oil sweating through the axle boot on that same side. Not bad but there is some. So I figure I need to jack it all up and check it out. Something tells me that I am going to be tearing into the axle and doing some servicing (Hubs/bearings/seals/wheel cylinders, etc.) That said would any of you be able to recommend the proper TM that would provide the clearest direction for digging into the front axle/hubs? Also any general guidance. Things to check first. Time and trouble saving advice would be welcomed and appreciated.

Thanks guys,

When I was backing the truck into the drive to pick up the stone I heard a strange kind of pop or cracking noise from the front right portion of the truck. I have been looking at the right front tire and it has looked as though it was leaning out from the top ever so slightly. Now I see some oil sweating through the axle boot on that same side. Not bad but there is some. So I figure I need to jack it all up and check it out. Something tells me that I am going to be tearing into the axle and doing some servicing (Hubs/bearings/seals/wheel cylinders, etc.) That said would any of you be able to recommend the proper TM that would provide the clearest direction for digging into the front axle/hubs? Also any general guidance. Things to check first. Time and trouble saving advice would be welcomed and appreciated.

Thanks guys,