fpchief

Well-known member

- 1,041

- 218

- 63

- Location

- South Alabama

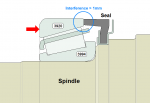

If the inner hub seal looks fine (meaning that rubber piece that wraps around the seal looks intact) do most just leave them alone? I have asked this question before and did not get much response. What is a good way to get the new hub seal started on the spindle? i took the front ones to a shop with a press but now i am working on the rear axles.