altoids

New member

- 30

- 2

- 0

- Location

- High Point, NC

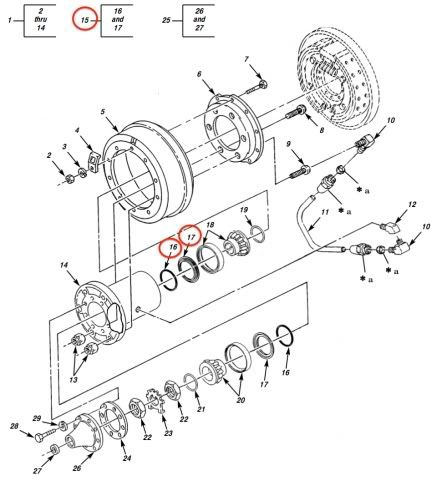

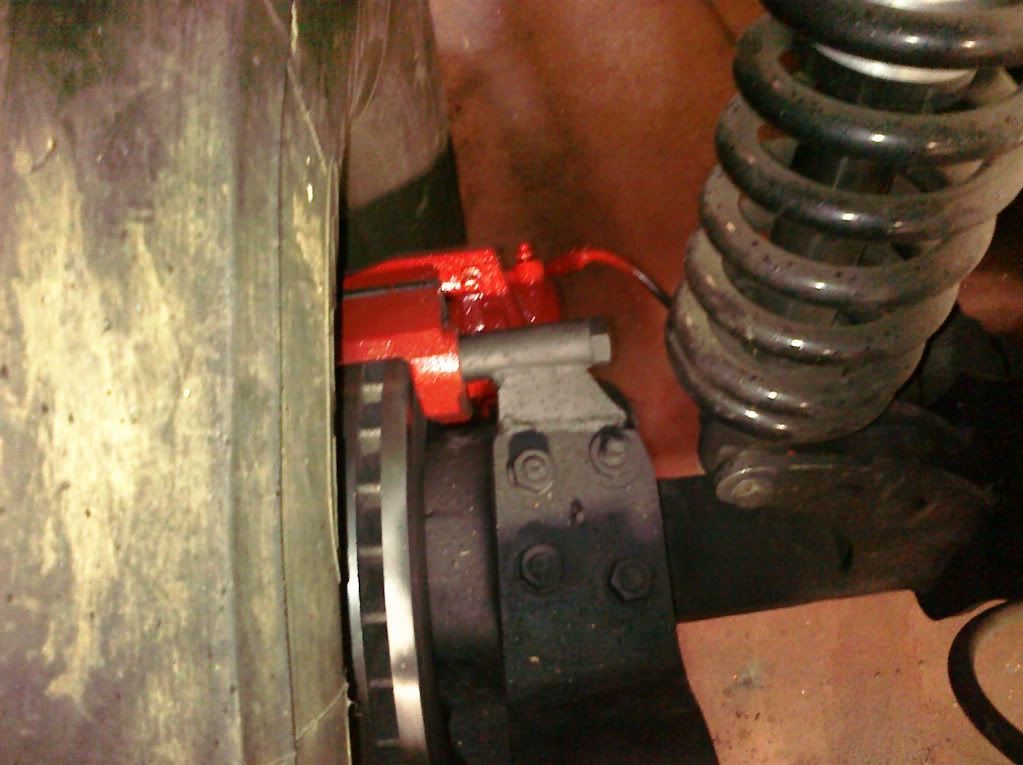

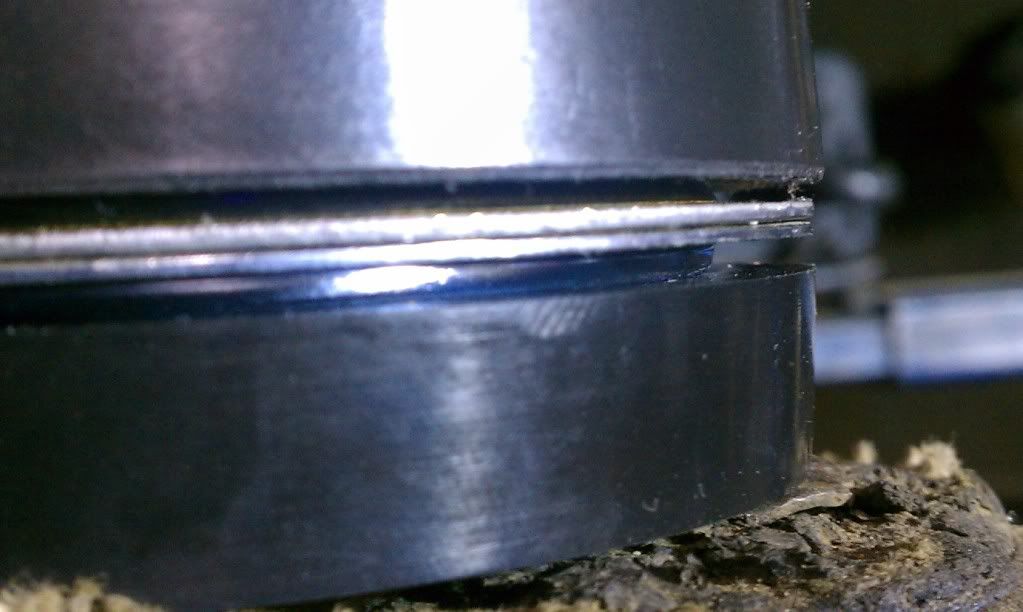

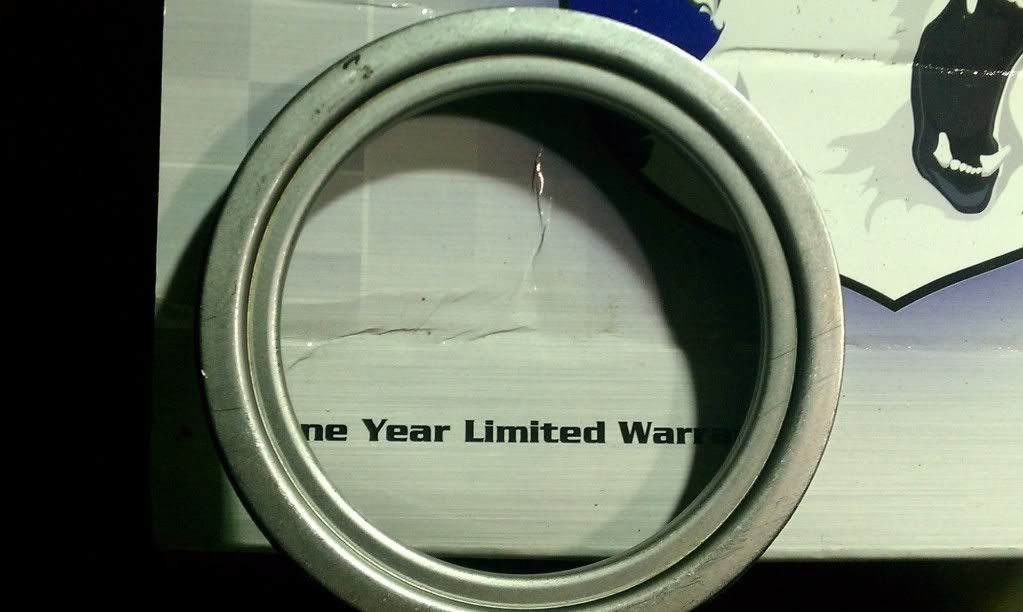

Back in October I put all new bearings & seals in front & rear axles. Took front apart to clean it up after going thru some mud (only taken front apart so far, rear axle is M35A3 so I'll check them later different style inner bearing) & it looks like it never had a seal there to begin with. Grease/dirt mixture in bearing (outer bearing still looks brand new thou) looks like old bearing I took out, they only have 2k miles on them. Is there a better way to seal the inner bearings? Did I press the seal on the spindle to far, should I have just tapped seal over lip & let the bearing press it on when I torque the bearings down? Any help is greatly appreciated. Not real pumped about repacking inner bearing ever 1k miles.