This is my first write up and I am doing it from memory so read the entire write up before performing any work. There may be some errors so let me know if you find any and I will make corrections. Writer implies no warranty or chance if success since he is not the one doing work. Briefly, if you break your stuff using this I am sorry but I am not taking responsibility for it. With that said, let us continue with some background and explanation of differences.

Using TM 9-2320-289-34 we will discuss the differences in a standard 1984 27Si alternator for a Cadillac Eldorado and the isolated ground alternator of a CUCV. This write-up will require you to refer to the TM-34 for reference so take the time and download it now if you have not already.

Starting with Section 4-2 on page 262 we will see images at item 6 on page 264 showing a cross section of how the insulating washers are used on studs through the rear of the case.

On page, 271 items 7 and 8 discuss some of the components that are different from a standard 27Si. First is the “bridge to rectifier jumper wire”. Second is out of view under the rectifier bridge referred to as the “rectifier bridge fiber insulator” it is a fiber washer that fits under the rectifier bridge and prevents that side from contacting the outer casing. Finally, the “negative terminal plastic insulator” is installed in the case on the other side of the rectifier bridge. This is the area that you will find a raised section inside the case indicating where you will ultimately drill a 21/64ths hole for the negative terminal plastic insulator. You will also only use insulated screws to secure the rectifier bridge and voltage regulator and brush holder assembly.

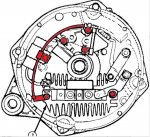

Attached is an image with the differences highlighted in red.

Think of it this way the rectifier bridge has the (+) and the (-) already as part of it and depending on the ground of the vehicle you are working with one side is already isolated from the case and directed towards a terminal thru the case. By adding the fiber washer and the insulated screws and jumper wire, you are effectively isolating both sides from the case and having each of them directed to a terminal. You have to carry this thru to the voltage regulator, which is stacked with the brush assembly also so you do not short it out.

Ok enough of the preliminary understanding now on to the instructions.

Materials required

· Old isolated ground alternator or parts from inside one

· New 27Si (1984 Eldorado) alternator … New to you works also but you may want to rebuild it if its used

Tools required

· Assortment of basic hand tools sockets etc.

· Drill with assortment of bits to include 21/64ths bit

· Ohmmeter

Old Alternator

1. Disassemble the case halves of the donor alternator and lay it so you can see the rectifier, brush assembly etc.

2. Remove the three nuts securing the stator to the rectifier and set the stator aside.(it may be stuck to the case half)

3. Remove the three insulating screws securing the voltage regulator, brush holder, and save them for use in the new alternator.

4. Remove the remaining screws holding the jumper wire and set it and the insulating screw used to connect it to the rectifier aside for use in the new alternator.

5. Remove the remaining screws that are on the inside holding the jumper plates to the rectifier so other than the (-) stud it is free (plates can be pushed aside rather than removed as long as the rectifier can be removed in a future step)

6. If not already done remove diode trio

7. Remove the nut holding the (-) stud thru the case

8. Gently pull rectifier from case with (-) stud paying close attention to the washer and plastic insulator stack

9. Remove the fiber washer from where the rectifier was positioned

New Alternator (You are voiding any warranty by opening a new alternator so do it at your own risk!)

10. Using toothpick or paperclip secure brushes of new alternator so they do not fall out when the case halves are separated.

11. Separate case halves of new alternator (separate piles of parts from new and old makes life easier later so keep that in mind)

12. As with you did with the old remove the stator of the new alternator and set aside.

13. If you did not have the brushes pinned properly in step 10 then repack them and secure with a toothpick or paperclip

14. Remove the diode trio from the new alternator. Unsecure all items from the rectifier and remove it from the case.

15. Take tape and cover the needle bearing in the rear of the case making sure it is covered so shavings and filings made in future steps do not get in it.

16. Locate the raised boss in the back of the case where the (-) stud should go thru the case and compare it to the old case.

17. Drill a small pilot hole from inside the case to outside centering it as the old case had it.

18. Make absolutely sure your pilot hole is where it should be and move if needed (you can’t undo the final hole so now is your chance to make corrections)

19. Once satisfied with your pilot hole use a 21/64ths size drill bit and chase your pilot hole to enlarge it to 21/64ths.

20. Check the inside of your case near the new hole and on the other end of where the rectifier will sit for additional positioning bosses in the case that could come in contact with the rectifier and or impede the seating of the fiber washer that will insulate the other side of the rectifier.

21. Clearance the case of the afore mentioned bosses with a dremmel tool or as I did use a very small drill bit to weaken them and remove them with pliers. (Do not drill to the outside when weakening the bosses with a small drill bit)

22. Check for a smooth flush finish to the removed boss area by placing washer in area and checking for any raised area and remove more material as needed.

23. Clean case inside of any shavings or filings (do a thorough job as you don’t want this getting into the works later)

24. Place (-) stud into slot in rectifier

25. Place plastic (-) stud grommet in case and set fiber washer over its threaded mounting hole

26. Lower rectifier with (-) stud into case half until seated and add insulating washer stack and nut to (-) stud

27. Placing one end thru tab on jumper wire secure other end of rectifier with an insulated screw making sure to get it thru the fiber washer under the rectifier.

28. Check case and rectifier with ohmmeter. Makes sure that case is not connected to (-) stud. If it is check that, the jumper wire is not laying inside the case completing the circuit. If it is, correct and retest. Of not check for other issues before proceeding.

29. Once insulated continue by removing cap mounting screw and placing center support of jumper wire on screw and re-securing cap.

30. Re connect cap to (+) side of rectifier with standard screw

31. Remove standard screw from brush holder /voltage regulator stack on opposite side of resistor from the side connected to the diode trio. Replace with insulated screw that is fed thru the end of the jumper wire. (refer to attached image for visable items)

32. Replace other screws as needed in brush holder/ regulator stack with insulated screws as needed.

33. Re attach diode trio and jumpers to (+) stud and (R) stud

34. Check all studs to case making sure nothing is shorted to the case using ohm meter

35. Replace stator and secure with nuts

36. Remove tape covering needle bearing

37. Put case halves back together and check with ohmmeter again.

38. Pull paperclip or toothpick allowing brushes to contact commutate rings again.

Congratulations, you have just taken a standard 27Si and made it an isolated ground unit. If you already had the parts, you could begin at step 10 and not disassemble the old unit but I recommend it for the positioning of the (-) stud. Once you do it a few times, you will not need to refer to an old case half. This took me about an hour to do with minimal tools but take your time and do it right the first time.