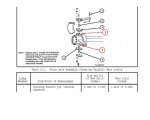

Front axle seal retainers

Just reviving an old thread with a Q. still waiting to be answered…. At that time (June 2007) I had posted some pics showing an axle housing with its seal retainer installed/removed and FreightTrain was wondering about the shape of that plate, not having a flat face…well, that was just the old style retainer but without the thrust washer in place and….

… for all of you with older (gasser) Deuces: if you ever plan to replace your worn CV-axle shafts with the later model U-joint axle shafts…. emmmh, don’t do what I did: don't pack everything nicely with grease and stuff them in, expecting they would simply interchange…! I found out today something that the TM's (my books, at least) don’t mention: U-joint shafts are about ¼” larger measured between thrust washers and won’t interchange unless the seal retainers were also swapped out for the new style ones, which are accordingly thinner!

My solution: put the old retainers in the lathe, remove the protruding thrust washer guide and reduce its height or total thickness, from initially 14mm to now 7mm.

BUT… I’m not overly exited about the new arrangement (neither what the factory did!): the old style retainers have a hardened steel ring pressed on as friction surface while on the newer ones the axle directly rubs against the soft face. Also I found that the new ones are more fragile and easily get distorted during removal. IMHO they should at least have made them of high grade steel and surface hardened…!

As a side note: U-joint axles might be stronger, but they do not rotate as smoothly as constant velocity axles do! Not a real problem though, for those who added lock out hubs and only occasionally need AWD!

Attached pics tell the rest… enjoy!

Gerhard