- 1,467

- 4,097

- 113

- Location

- Portland, OR

When addressing loose and corroded connections at the LBCD I noted that several studs were loose in the housing. After confirming with several members that this was a clear indication of failure (the unit is no longer sealed against moisture at the very least), I procured and installed a replacement - which seems in OK condition - no corrosion evident anywhere that I can see, and all studs tight in their epoxy. No discoloration around the back side where it's potted with silica sand and silicone. Build date of 2011.

I used Dow Molykote 111 on the studs and wire terminals:

I installed and tested the truck prior to disassembly of the old unit.... which I guess was doing..... something?!? Though I'm not sure what use it could have been:

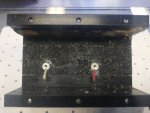

I need to sit down and attempt a more in-depth autopsy and actually test these caps but from first looks it appears all the capacitors have failed and leaked inside the case. The silicone at the bottom edge was already loose from the housing and the corner pried away easily.

Note that none of that is visible without removing the unit from the truck. The only thing I could see with it installed was that the studs were loose in the epoxy.

The serial number of my original 2008 box was in the 2x,xxx range, while the 2011 unit was 60,xxx range.

I now wonder what the use-by date of these is and if anyone else has evidence of capacitor leakage. I'm also curious what symptoms we are likely to see with this failure mode. My 14v side was tending to fluctuate quite a bit especially immediately after cold start - the gauge would swing from around 13 up to 14 back and forth a bit. After driving for a while it would settle out around 14v and seemed to hold steady. After starting it up with the new box it seemed to fluctuate less, though there was still a bit of a swing - maybe half a volt this time. After what seemed like a shorter time the voltage's were both steady on 28v and 14v. But this wasn't a totally cold start since I had to move the truck to lower the spare for access to the LBCD.

As I understand it, all the A1 trucks have this unit. Mine specifically is an A1R with the 260 amp alternator. For reference.

Rick

I used Dow Molykote 111 on the studs and wire terminals:

I installed and tested the truck prior to disassembly of the old unit.... which I guess was doing..... something?!? Though I'm not sure what use it could have been:

I need to sit down and attempt a more in-depth autopsy and actually test these caps but from first looks it appears all the capacitors have failed and leaked inside the case. The silicone at the bottom edge was already loose from the housing and the corner pried away easily.

Note that none of that is visible without removing the unit from the truck. The only thing I could see with it installed was that the studs were loose in the epoxy.

The serial number of my original 2008 box was in the 2x,xxx range, while the 2011 unit was 60,xxx range.

I now wonder what the use-by date of these is and if anyone else has evidence of capacitor leakage. I'm also curious what symptoms we are likely to see with this failure mode. My 14v side was tending to fluctuate quite a bit especially immediately after cold start - the gauge would swing from around 13 up to 14 back and forth a bit. After driving for a while it would settle out around 14v and seemed to hold steady. After starting it up with the new box it seemed to fluctuate less, though there was still a bit of a swing - maybe half a volt this time. After what seemed like a shorter time the voltage's were both steady on 28v and 14v. But this wasn't a totally cold start since I had to move the truck to lower the spare for access to the LBCD.

As I understand it, all the A1 trucks have this unit. Mine specifically is an A1R with the 260 amp alternator. For reference.

Rick