Looking for the specific difference between "Split Rings" and "Split Rims/Widowmaker"

(Not sure if this should be under Deuce or Safety)

About a year and a half ago I picked up a 1980 C20 for $150 from a GI on Fort Lewis. I brought it over to the folks house to work on it and my grandfather, a mechanic of 40 years whos opinion I respect in most every way, wouldn't come within 20 feet of the truck due to the split rim wheels. I managed to find some great wheels and tires at pick a part fr $20 and replaced the 2 split rims and made them go away, and all was good.

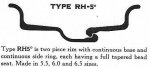

Now, I just bought my Deuce. I have read a few posts explaining that these are ok, but I need to invest in a 3 foot length of cheater hose for inflation's. Every post I have read so far just says that they are different, but doesn't explain why they are different.

Id take your word for it of course, but grand pap wont, so I would like some facts to present when I have the conversation about it.

(Not sure if this should be under Deuce or Safety)

About a year and a half ago I picked up a 1980 C20 for $150 from a GI on Fort Lewis. I brought it over to the folks house to work on it and my grandfather, a mechanic of 40 years whos opinion I respect in most every way, wouldn't come within 20 feet of the truck due to the split rim wheels. I managed to find some great wheels and tires at pick a part fr $20 and replaced the 2 split rims and made them go away, and all was good.

Now, I just bought my Deuce. I have read a few posts explaining that these are ok, but I need to invest in a 3 foot length of cheater hose for inflation's. Every post I have read so far just says that they are different, but doesn't explain why they are different.

Id take your word for it of course, but grand pap wont, so I would like some facts to present when I have the conversation about it.

Last edited: