- 3,317

- 3,530

- 113

- Location

- NORTH (Canada)

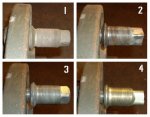

I flipped the hubs a long time ago and did what seemed logical to do: spin the thimbles all the way onto the lug bolts to re-use the rear lug nuts.

Lately, I have been reading that one should not do this, as it can cause the lug bolts to break. So....I need to get 24 front lug nuts and take the thimbles off? I must have missed that info in the "flip your hub" threads...

BTW, I never load down the truck...run empty or lightweight.

Lately, I have been reading that one should not do this, as it can cause the lug bolts to break. So....I need to get 24 front lug nuts and take the thimbles off? I must have missed that info in the "flip your hub" threads...

BTW, I never load down the truck...run empty or lightweight.