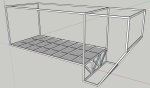

Had a pretty productive weekend. Made an interior for the cab:

Painted the engine blanket with rubberized paint (looks great but the verdict is still out on if it will fully cure)

Headliner looks pretty good:

I also made an overhead console as well (sorry for crappy pic):

The center panel of the rear wall remains empty because I intend to make a pass-through to the camper body. I don't want to waste the time and energy to make the panel now and then modify or completely re-make it later.

I went with a rather industrial theme on the interior because it is a truck and we don't care about flashy stuff. I am pretty happy with it and the wifey thinks it looks fantastic, so I'm calling it good! I need to touch up some places where I didn't get the black paint down on the interior as thickly as I thought, but it definitely has made the cab a more comfy-seeming place to be. Still to come is a bit of carpet on the floor under the seating areas, and if the rubberized paint doesn't cure, over the engine area as well.

Next up is wiring in all the crap that I've been accumulating- interior lighting, exterior lighting, radio, CB, reverse cam, mirror switch, etc... I picked up a simple 12 circuit panel which I will wire all that crap out of independently. I found switches which fit the punchouts on the dash though, so that makes the install very appealing for things which need switches. I am struggling a little bit logistically with how to wire up the overhead to be able to install and remove it when necessary. This will take a few additional connectors and some pre-planning, but it is doable.

I also need to work in the glovebox doors for the console as well, so it's usable more than just as an overhead electronics space.

These are the last few hurdles I want to clear prior to starting the sub-frame and box build-out. I already feel like I have a million moving pieces to this project and I'd like to get some wrapped up before opening another can of new ones.