- 3,319

- 3,537

- 113

- Location

- NORTH (Canada)

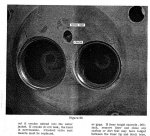

Hairline cracks on the heads are normal to an extent, especially if the heads are older and are not from the last castings in the late 1980' . The TM specifically mentions that the cracks within specs do not make a head unserviceable.

Sent from my SM-G991W using Tapatalk

Sent from my SM-G991W using Tapatalk