M51clueless

Member

- 38

- 29

- 18

- Location

- Tennessee

Need some help

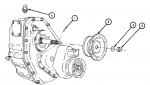

I cannot get the upper shaft to slide out.

Have not found the step by step in the tm for how to take the nose piece off the front to the transfer case ,

what I have done is

remove the front driveshaft

disconnect the air lines

remove the driveshaft between the transmission and transfer case.

disconnect the speedometer cable

worked real hard to get the upper shaft to move , was only able to get 1/4 inch or so.

finally saw the cover on the back side of the transfer case, took it off and found a snap ring, was sure I had it figured out but sill no luck getting the upper shaft to budge

I cannot get the upper shaft to slide out.

Have not found the step by step in the tm for how to take the nose piece off the front to the transfer case ,

what I have done is

remove the front driveshaft

disconnect the air lines

remove the driveshaft between the transmission and transfer case.

disconnect the speedometer cable

worked real hard to get the upper shaft to move , was only able to get 1/4 inch or so.

finally saw the cover on the back side of the transfer case, took it off and found a snap ring, was sure I had it figured out but sill no luck getting the upper shaft to budge

Attachments

-

101.4 KB Views: 32

-

91.7 KB Views: 33

-

129.2 KB Views: 32

-

139.7 KB Views: 33