red

Active member

- 1,988

- 26

- 38

- Location

- Eagle Mountain/Utah

Costs a case of beer for me to open up the TM's for others and I do collect that haha.So we have the two great 5 ton race truck builders in here but we can't figure out whether the hubs are grease or oil? For shame...

So where does that leave us? Well let me see if I can ass-ist.

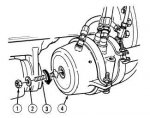

The rear hubs are originally grease lubed. There is an inner and outer seal on the A0/A1 trucks. If the inner seal leaks then gear oil will travel to the bearings. This is fine, and how I run my truck, AS LONG AS the outer seal is good. If the outer seal leaks then you end up with oil in the brakes.

So, in your picture Jaws4518, there is no grease in there. You say the seals are good so this would mean no oil either. That looks pretty dry to me. I think someone forgot the grease at rebuild. Wouldn't be the first time someone found this problem. Did any oil come out when you pulled the axle?

Take your pick, grease or oil bath. Both are fine. If you choose oil bath just make sure your outer seal is good so you don't soak the brakes. I've been running mine like this for about 2 years now. The bearings don't care what they're lubed with...oil, grease or a mix of both.

Problem with the oil bath plan is the inner seal by the brakes, it's not designed to keep oil in, just to keep crap out.