lacoda56

Member

- 775

- 7

- 18

- Location

- Rochester, Washington

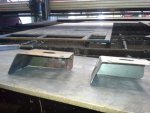

Do you mean the support bracket in fig. 344? That's the piece I sent. It's angled on both sides as pictured, but I don't think it would need to be.

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

Do you mean the support bracket in fig. 344? That's the piece I sent. It's angled on both sides as pictured, but I don't think it would need to be.

I am still not entirely certain on the pillow bearing bracket. If you could pull yours and either send it to me or compare the prototype measurements and shape to yours it would be helpful.If there is anything else you need, we don't have our winch mounted due to the plow being in the way until we can cut off some brackets (for the plow, not the winch), but everything else is there on the truck still down to the driveshafts. Might make it easier to get measurements.

That looks good!! What else are you going to start making?