tsdp

New member

- 5

- 0

- 0

- Location

- henderson, ky

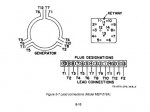

Over the past couple weeks, I have been trying to get my recently purchased MEP-017 to "generate".

I have read the manual, read posts on this forum, purchased a new voltage regulator, and have many hours invested.

The voltage output is low (30 - 50 volts), the hz meter reads low and does not raise if I throttle up the engine. Both voltage and hz meters work fine on 120 VAC house current.

The field flash circuit works, exciter field resistance in withing spec. Continuity is complete everywhere I check it., the 3 diodes are good.

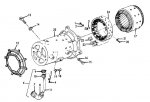

Today, I took everything apart to inspect and check the rotor resistance. The book says the rotor winding to rotor frame should be 8.8 ohms +- 5%. This spec is off just a bit., I am getting about 9.8 ohms with a couple different meters.

I am thing about running the generator with the voltage regulator powered up by 120VAC house current. just to see what happens.

So far, I am defeated by this generator, help me if you can.

Thank You, Trent

I have read the manual, read posts on this forum, purchased a new voltage regulator, and have many hours invested.

The voltage output is low (30 - 50 volts), the hz meter reads low and does not raise if I throttle up the engine. Both voltage and hz meters work fine on 120 VAC house current.

The field flash circuit works, exciter field resistance in withing spec. Continuity is complete everywhere I check it., the 3 diodes are good.

Today, I took everything apart to inspect and check the rotor resistance. The book says the rotor winding to rotor frame should be 8.8 ohms +- 5%. This spec is off just a bit., I am getting about 9.8 ohms with a couple different meters.

I am thing about running the generator with the voltage regulator powered up by 120VAC house current. just to see what happens.

So far, I am defeated by this generator, help me if you can.

Thank You, Trent