- 4,039

- 6,761

- 113

- Location

- MA

GIve it time to work up to full load. Put a whole can of seafoam into the tank with your fuel, and step the loads up in whatever increments you can.

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

I understand all the issues that can arise with these. I am prepared if i have to replace well nuts and fuel lines or fuel tank floats. Was just surprised how much wet stacking from that few of hours. Also the 100 hour service had been performed but the air filter looks terrible. I will not be working on it today, because i spent my day up at the MV show in Findlay Ohio. Had a good time.If it's been sitting a while, many of these units will leak from the fuel return lines from the injectors, so don't get your heart set on getting it all up to snuff in a single day.

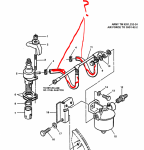

My MEP-802a is leaking from the shared fuel rail rubber lines supplying the fuel injection pumps. Looks like 1/4" line, But appears to be a bit of a pain to change with the external crimps on the lines. What size line do you use for this? Whatever size lines they are mine are leaking all over as I started mine up for its first 20 seconds of new life. Depending on how that goes (getting this changed out) and then seeing if there are any other imminent leaks, I expect to be buying some of the parts off your EBay store.If it's been sitting a while, many of these units will leak from the fuel return lines from the injectors, so don't get your heart set on getting it all up to snuff in a single day.

These are also very low pressure so depending how snug the hose you use on the injectors and tees you may not even need clamps. I think Colt did some small zip ties on his video for changing these lines.My MEP-802a is leaking from the shared fuel rail rubber lines supplying the fuel injection pumps. Looks like 1/4" line, But appears to be a bit of a pain to change with the external crimps on the lines. What size line do you use for this? Whatever size lines they are mine are leaking all over as I started mine up for its first 20 seconds of new life. Depending on how that goes (getting this changed out) and then seeing if there are any other imminent leaks, I expect to be buying some of the parts off your EBay store.

Nice YouTube vids as well.

Pic below shows the two lines of mine that are leaking.

View attachment 915070

good example of proactive maint right there.. nobody should wait for anything to wet-stack because it takes longer and more load time to undo it .. That is if it hasn't already gone on for too long and the damage done ... Whenever possible, get a decent load on it after warmup.. Mine sometimes have short run times (less than 30 minutes) several times a day, but at least once or twice a week they each get to run heavy stuff like 5HP compressors, welders, etc for 2 or 3 hours.. They don't get a chance to wet-stack but I understand the temptation to give them light loading and short run times due to fuel etc.. In warm weather I run a special mix of fuel/WVO in mine if they are gonna run more than a couple hours, to help ease the painAny surplus generator should be loaded at least to 100% load. Whether is shows signs of wet stacking or not.

None of us here need to know any personal reasons why, and I see you're in texas and depending on where one is in the state, one can be either freezing or very warm at night .. But the situation is just begging someone to ask.. Do you really have to run the AC overnight?I used mine at my off-grid place & during the night, the A/C units don't run hard as the air temperature isn't as high & almost no load is on the unit for probably 45 minuets of every hour.

Were the lines you replace on the injection pumps 1/4? The Fuel return is 3.5mm, but this hose looks a bit bigger.These are also very low pressure so depending how snug the hose you use on the injectors and tees you may not even need clamps. I think Colt did some small zip ties on his video for changing these lines.

MEP 802A & 803A Fuel Return Line Improvement (youtube.com)

Yes, it stays into the 100deg range at night in summer & in the single digits in the winter. With people in an enclosed space, it gets over 120deg inside very quick... at night. You can imagine daytime! Ended up putting a second window A/C in. I had a Honda for a bit and it hated it. Inverter didn't handle the heat well. Why spend all that money on another generator to maintain, have another fuel source, and have to swap over? All the save just a few ounces of fuel consumption per hour? The inverter Honda's run at a higher RPM idling than the MEP-802A regularly. In the end, it's not even close to cost effective, & way more convenient to just have the one with the much more stable fuel. Same reason I have not invested in any big solar yet. Gasoline doesn't fair well in that heat. It bakes off. Fuel just swell massively. You look at it wrong & it will go up. Diesel is much better in the dry heat. When I need the power for the larger stuff, I have it too.None of us here need to know any personal reasons why, and I see you're in texas and depending on where one is in the state, one can be either freezing or very warm at night .. But the situation is just begging someone to ask.. Do you really have to run the AC overnight?.. If so, a small gas genny like a honda eu3000 (true sine) is very reliable, quiet, fuel-efficient, and handle a decent load .. They also have a selectable no-load idle feature so that it's not at high rpm 100% of the time, the rpm varies automatically depending on load

that genny is running off grid in montana for the past 3 years, not a hiccup that i have heard about.ROPU!! That was a great piece of equipment, and a great gen set.

Hey! That looks familiar.This is what a 005 30kw that was locked up from wetstacking looks like when you finally get it to roll over and start.

- YouTube

Enjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTube.youtube.com