Walt4653

New member

- 71

- 0

- 0

- Location

- Lincoln RI

Helping a friend who purchased a MEP 002 with 8 hrs, reset by letterkenny in 05

did all the necessary prep work, cleaned tank, new filters, new fuel etc.

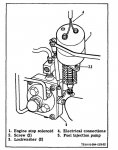

Tried to start no go, turns over does not start, no smoke coming from exhaust, glow plugs work, etc, noticed a old ip painted brown, rest of genset green. Took out one injector no fuel going through but looked clean,fuel lines return fuel,what am I missing here. Could it be the ip, and how careful do I need to be to take apart, and what am I supposed to see. Took line off ip no fuel squirting out when turning over.

please help

Thanks Walt

did all the necessary prep work, cleaned tank, new filters, new fuel etc.

Tried to start no go, turns over does not start, no smoke coming from exhaust, glow plugs work, etc, noticed a old ip painted brown, rest of genset green. Took out one injector no fuel going through but looked clean,fuel lines return fuel,what am I missing here. Could it be the ip, and how careful do I need to be to take apart, and what am I supposed to see. Took line off ip no fuel squirting out when turning over.

please help

Thanks Walt

Last edited: