Kemper

Member

- 36

- 16

- 8

- Location

- Centerville, NJ

Because I didn’t find much when I searched for info.

Got a warm 18k severe duty winch for a good price off eBay. Take off from an MRAP.

Planning on 100% bolting the bumper to the winch box and welding the winch box to the torsion tube. That way the bumper can be removed if it gets damaged.

Steel: A572 GR60 5/16”

Still to do:

Trim excess steel from top edge

Drill holes for mounting hw

Drill holes for access to torsion tube

Burn slot for cable

Weld everything

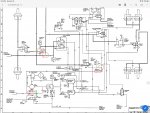

Wire everything

Build cover that will be flush with the top of the bumper

Build mounting plates for bumper to winch enclosure

Power coast finished assembly

Here are some progress pics:

Sent from my iPhone using Tapatalk

Got a warm 18k severe duty winch for a good price off eBay. Take off from an MRAP.

Planning on 100% bolting the bumper to the winch box and welding the winch box to the torsion tube. That way the bumper can be removed if it gets damaged.

Steel: A572 GR60 5/16”

Still to do:

Trim excess steel from top edge

Drill holes for mounting hw

Drill holes for access to torsion tube

Burn slot for cable

Weld everything

Wire everything

Build cover that will be flush with the top of the bumper

Build mounting plates for bumper to winch enclosure

Power coast finished assembly

Here are some progress pics:

Sent from my iPhone using Tapatalk