Pawnshop

Active member

- 1,798

- 20

- 38

- Location

- Austin/Cedar Park Texas

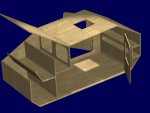

So I have decided to build a teardrop style camper on a M101 trailer I have and had a thought: instead of removing the body tub why not cut off all of the vertical surfaces and make a flat bed, like a M116 genset trailer? A flat bed would give me fenders and a wide flat (sort of flat) surface to work on, and if it does not work I can still just build on the bare frame.

I thought that a 7" grinder with a cutting disc would be just the ticket, but after getting only about 5' of cut from $8 worth of discs I decided to rethink. A sawzall was suggested so I gave it a whirl, BINGO! Now over the years when the question of which cutting tool to use came up, and a sawzall was suggested, I was always skeptical, but after today I am now a firm believer in the tool!

I DID learn a few things:

1-do your best to not bend the blade, they get all wobbly...

2-do NOT try to cut the welds, they are a lot harder than the sheet metal and will burn up the blade, they don't cut after they get too hot...

I still have some grinding to do, and some sandblasting, but so far so good:

pix:

1-trailer before

2-after $8 of cutting discs

3-pile-o-body (cut into recycling bin sized chunks, note burnt up blade)

4-the Hero tool

5-blades

6-after

7-remaining vertical lip

8-more after

I thought that a 7" grinder with a cutting disc would be just the ticket, but after getting only about 5' of cut from $8 worth of discs I decided to rethink. A sawzall was suggested so I gave it a whirl, BINGO! Now over the years when the question of which cutting tool to use came up, and a sawzall was suggested, I was always skeptical, but after today I am now a firm believer in the tool!

I DID learn a few things:

1-do your best to not bend the blade, they get all wobbly...

2-do NOT try to cut the welds, they are a lot harder than the sheet metal and will burn up the blade, they don't cut after they get too hot...

I still have some grinding to do, and some sandblasting, but so far so good:

pix:

1-trailer before

2-after $8 of cutting discs

3-pile-o-body (cut into recycling bin sized chunks, note burnt up blade)

4-the Hero tool

5-blades

6-after

7-remaining vertical lip

8-more after

Attachments

-

79 KB Views: 205

-

97.3 KB Views: 199

-

97.8 KB Views: 195

-

56.1 KB Views: 184

-

60.8 KB Views: 167

-

78.9 KB Views: 190

-

100.6 KB Views: 179

-

93.3 KB Views: 205