- 371

- 1,047

- 93

- Location

- Utah, Murray, United States

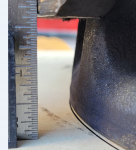

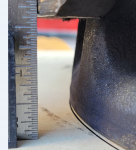

I am having some issues with interpreting the "markings" in the TM on adjusting the pressure plate. My pressure plate that was removed, and worked perfectly, doesn't even come close to the spec (I am assuming here as I am struggling to understand where the measurement surfaces are) and neither does my new one I am looking to mount.

The TM says the distance between the pressure plate ..... ring???top is to be 1.281" but there is no "ring" to measure to and even if this ring is the finished surface on the side of the pressure plate it is not the same "thickness" on the new one as the old one. Also the finger adjustment... and the "top of the pressure plate, that the fingers are to be measured to, where the heck is that spot on the top of the plate? That makes no sense to me.

I will get some measurements for the depth of the pilot bearing in the face of the transmission when I have a sec to see what the compounded distance is to ensure that the bearing will release from the three fingers when in the retracted position. Whomever wrote this section of the TM was drunk. I see no markings on the pressure plate to indicate a "measurement" surface or ring or anything in either of these two spots referred to here:

So far this is what I had:

Pressure plate bolt face to the face of the old pressure plate=1.625", New=1.437", TM I think wants 1.281... to the whatever part of the pressure plate...

Old Clutch thickness= .430, New clutch thickness .440

Distance from flywheel pressure plate mounting surface to the clutch face - 1.770 inches

This gives a compression sping load with the original pressure plate of .285 inches.

This gives a compression spring load on the non adjusted unit of.107 inchs.

If I follow the TM for what I think it is asking I would have a negative compression of -0.049"

ON this spring load in inches measurement between the old and the new. .285 vs .107. These are my thoughts:

The springs will be at the same compression distance when mounted on the flywheel when in contact with the clutch disc. This is designed into the actual pressure plate and the springs chosen. They only thing that could screw up the clutch not "binding" on the clutch disc is if the plate height was to be adjusted to compress the springs (bringing the plate height up into the pressure plate) so the plate was already compressed higher into the plate than the disc will touch. This would be crappy. And this height is what I would get if I adjusted to the 1.281 distance. I would have a negative distance of .049.

The higher the adjustment distance from the pressure plate mounting face to the pressure plate clutch face only relaxes/releases spring pressure at the extended distance.

Note!: If it plate was too high/extended there could be an issue of not being able to fully disengage the clutch as the plate would just keep extending from its compressed position to what the maximum extended distance would be.

The way I see it if I installed the new pressure plate as it is I would have basically a .107" clutch engagement distance from initial touch to fully engaged and the peddle distance from initial contact to this fully engaged contact would happen over much shorter distance .107" than what I had previously where the initial contact and the fully engaged happened over .285", a peddle travel feel nearly three times the distance between just sllipping and fully engauged. Now my clutch worked perfectly for thousands of miles (The truck has something like 21,000 miles on it) with the height at what you see here in the pics basically a 1 5/8" height from the floor is what I am leaning toward adjusting it to. Same as it was before.

The TM says the distance between the pressure plate ..... ring???top is to be 1.281" but there is no "ring" to measure to and even if this ring is the finished surface on the side of the pressure plate it is not the same "thickness" on the new one as the old one. Also the finger adjustment... and the "top of the pressure plate, that the fingers are to be measured to, where the heck is that spot on the top of the plate? That makes no sense to me.

I will get some measurements for the depth of the pilot bearing in the face of the transmission when I have a sec to see what the compounded distance is to ensure that the bearing will release from the three fingers when in the retracted position. Whomever wrote this section of the TM was drunk. I see no markings on the pressure plate to indicate a "measurement" surface or ring or anything in either of these two spots referred to here:

So far this is what I had:

Pressure plate bolt face to the face of the old pressure plate=1.625", New=1.437", TM I think wants 1.281... to the whatever part of the pressure plate...

Old Clutch thickness= .430, New clutch thickness .440

Distance from flywheel pressure plate mounting surface to the clutch face - 1.770 inches

This gives a compression sping load with the original pressure plate of .285 inches.

This gives a compression spring load on the non adjusted unit of.107 inchs.

If I follow the TM for what I think it is asking I would have a negative compression of -0.049"

ON this spring load in inches measurement between the old and the new. .285 vs .107. These are my thoughts:

The springs will be at the same compression distance when mounted on the flywheel when in contact with the clutch disc. This is designed into the actual pressure plate and the springs chosen. They only thing that could screw up the clutch not "binding" on the clutch disc is if the plate height was to be adjusted to compress the springs (bringing the plate height up into the pressure plate) so the plate was already compressed higher into the plate than the disc will touch. This would be crappy. And this height is what I would get if I adjusted to the 1.281 distance. I would have a negative distance of .049.

The higher the adjustment distance from the pressure plate mounting face to the pressure plate clutch face only relaxes/releases spring pressure at the extended distance.

Note!: If it plate was too high/extended there could be an issue of not being able to fully disengage the clutch as the plate would just keep extending from its compressed position to what the maximum extended distance would be.

The way I see it if I installed the new pressure plate as it is I would have basically a .107" clutch engagement distance from initial touch to fully engaged and the peddle distance from initial contact to this fully engaged contact would happen over much shorter distance .107" than what I had previously where the initial contact and the fully engaged happened over .285", a peddle travel feel nearly three times the distance between just sllipping and fully engauged. Now my clutch worked perfectly for thousands of miles (The truck has something like 21,000 miles on it) with the height at what you see here in the pics basically a 1 5/8" height from the floor is what I am leaning toward adjusting it to. Same as it was before.

Last edited: