- 3,657

- 29

- 48

- Location

- Dallas, Texas

Today the box was set. The truck was started for the first time in a while. Big smoker at 7 degrees F till it caught and ran. Lots more little details.. The temp was too low to paint so we heated the rattle cans and the hard top so the paint would spray and stick. Someone knocked over a can of Dr Pepper, notice the spill froze instantly to the wood. Check the fit with the oak planks and with the lift gate height. It is perfect and will articulate fully.

Here are some questions about the M818-

This beast does not like the cold weather and takes alot of cranking to start. Normal for the Cummins?

There is/was a problem with an air leak in the fuel system,we think we got it, will know more tomorrow when we go to start it. However, a symptom the engine shows is that when stepping on te throttle, the engine sputters a bit before coming up to RPM. The nature of the problem seems to be more of a delay of power than a loss of power. The problem was noticed by Stan and Brian when the truck was recovered. Could this be an air leak getting sucked into the fuel lines or some other issue maybe with the governor? The truck does come up to speed OK once it gets past this little delay and has plenty of power on the open road.Cummins experts pls. speak up!!

Soon the RADAR will be installed.

Here are some questions about the M818-

This beast does not like the cold weather and takes alot of cranking to start. Normal for the Cummins?

There is/was a problem with an air leak in the fuel system,we think we got it, will know more tomorrow when we go to start it. However, a symptom the engine shows is that when stepping on te throttle, the engine sputters a bit before coming up to RPM. The nature of the problem seems to be more of a delay of power than a loss of power. The problem was noticed by Stan and Brian when the truck was recovered. Could this be an air leak getting sucked into the fuel lines or some other issue maybe with the governor? The truck does come up to speed OK once it gets past this little delay and has plenty of power on the open road.Cummins experts pls. speak up!!

Soon the RADAR will be installed.

Attachments

-

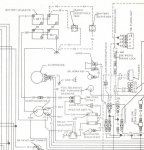

36 KB Views: 72

-

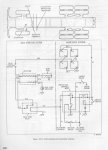

76.1 KB Views: 84

-

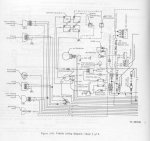

87.8 KB Views: 79

-

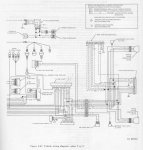

89.2 KB Views: 81

-

92.7 KB Views: 98

-

37 KB Views: 70

Last edited: