Dasgog

Active member

- 182

- 154

- 43

- Location

- Tucson, AZ

Hello!

So I was looking through some pages and game uponhttps://www.steelsoldiers.com/upload/M35/TM9-2320-209-34-2-1.pdf

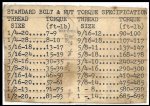

Great link. But I was wondering, am I to assume that any given bolt size no matter where it goes will have a set torque for it?

Like all and any 9/16 (example) in the truck will have the same torque based on the style of bolt used?

So I was looking through some pages and game uponhttps://www.steelsoldiers.com/upload/M35/TM9-2320-209-34-2-1.pdf

Great link. But I was wondering, am I to assume that any given bolt size no matter where it goes will have a set torque for it?

Like all and any 9/16 (example) in the truck will have the same torque based on the style of bolt used?