maverick

Member

- 249

- 1

- 18

- Location

- Southern England

Hi guys,

I need to pick your brains.

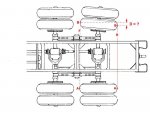

Back in 2007 my M54 A2 was hit buy a semi rig during a trip back from a show. Luckly nobody was hurt, the rig was written off by the insurance company but my M54 didn't come of to bad at all. I was only hit in the last 3 foot on the passenger side rear (don't forget we drive on the wrong side of the road over here) it was mainly cargo bed damage but he did hit the last axle outer wheel. well after checking everything and having the damage repaired i found nothing wrong with the axle except a buckled wheel which i replaced. Well after the 2008 season i noticed that the two passenger tyres on the last axle are wearing away a lot quicker than the rest of the tyres on the truck. Ive rechecked the axle, no damage no leaks, checked tyres and wheels no problem. Jacked up the rear and took drive shaft off and spun wheels all run smooth no knocks, bangs grinding or anything.

so what i need to know is can anybody recommend anything i need to check or have any ideas why its just the two tyres that are wearing on just one side of the axle.

Thanks in advance

I need to pick your brains.

Back in 2007 my M54 A2 was hit buy a semi rig during a trip back from a show. Luckly nobody was hurt, the rig was written off by the insurance company but my M54 didn't come of to bad at all. I was only hit in the last 3 foot on the passenger side rear (don't forget we drive on the wrong side of the road over here) it was mainly cargo bed damage but he did hit the last axle outer wheel. well after checking everything and having the damage repaired i found nothing wrong with the axle except a buckled wheel which i replaced. Well after the 2008 season i noticed that the two passenger tyres on the last axle are wearing away a lot quicker than the rest of the tyres on the truck. Ive rechecked the axle, no damage no leaks, checked tyres and wheels no problem. Jacked up the rear and took drive shaft off and spun wheels all run smooth no knocks, bangs grinding or anything.

so what i need to know is can anybody recommend anything i need to check or have any ideas why its just the two tyres that are wearing on just one side of the axle.

Thanks in advance