-

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

Who has an MEP-016E?

- Thread starter derf

- Start date

More options

Who Replied?jas67

New member

- 82

- 0

- 0

- Location

- Palmyra,PA

I have two one. It has a electric

lift pump. The lift pump is a 2 inch dia. By about 5 inch cylinder.

lift pump. The lift pump is a 2 inch dia. By about 5 inch cylinder.

Is that in addition to the Auxiliary Fuel Pump?I have two one. It has a electric

lift pump. The lift pump is a 2 inch dia. By about 5 inch cylinder.

Are there 2 electric pumps?

Or, did they re-plumb the AFP as a lift pump?

The 016Bs have an Auxiliary Fuel Pump that fills the fuel tank from an external source. I believe it is controlled by the fuel tank float switch. It is activated in the "Run Aux Fuel" position of the main switch.

I can't find much info on the MEP-016Es but I do know they exist and the E designation is correct:

Attachments

-

33.3 KB Views: 87

- 4,056

- 146

- 63

- Location

- Ponchatoula LA

it dont have to have that pump running for the eng to run.. it draws gravity feed off the little tank on top. that pump only fills that "day tank" set up from the bottom tank or another aux. tank source

OK, thanks. Mine is missing some parts and has some wires disconnected. So, I'm going to strip it down a little to lighten it. I should have some spare parts for the classifieds soon, ASK panels, wiring harness, etc.it dont have to have that pump running for the eng to run.. it draws gravity feed off the little tank on top. that pump only fills that "day tank" set up from the bottom tank or another aux. tank source

I got the Yanmar started today. I haven't re-connected the gen head wiring yet but the motor runs fine.

I put oil in, loosened the fuel line at the injector, held the compression release, and pulled the rope about 5-6 times until some fuel started leaking form the loose line at the injector.

I tightened the line, disengaged the compression release, pulled the rope slowly until it got to compression, flipped the compression release, gave the rope one good pull, and she fired right up.

Since the unit is missing a few parts and because I want it to be lighter I'm going to lose the starter and just start it with the pull rope (one advantage of the Yanmar). The electric fuel solenoid was missing, but an adjustment was all that was needed to get the stock Yanmar manual fuel shutoff mechanism working again.

It looks like this unit was in the middle of an incomplete Yanmar repower. It was an MEP-701A, not an MEP-016A, and the Yanmar is an L100, not the smaller L70. The muffler was loose and the exhaust gasket was with the unit but not installed. The fuel return line was there but not connected. The motor looks new. I pulled the valve cover to inspect and everything inside looked new.

I still have to go through the wiring and see what is not needed since it will be manual start.

I thought about converting the unit to 12V electric start (new 12V starter and battery) but it looks like the gen head gets 24V from the motor to feed the field circuit. I think it could be done with a 12V/24V regulator but I'd rather not have to install/maintain a battery if it isn't necessary.

I put oil in, loosened the fuel line at the injector, held the compression release, and pulled the rope about 5-6 times until some fuel started leaking form the loose line at the injector.

I tightened the line, disengaged the compression release, pulled the rope slowly until it got to compression, flipped the compression release, gave the rope one good pull, and she fired right up.

Since the unit is missing a few parts and because I want it to be lighter I'm going to lose the starter and just start it with the pull rope (one advantage of the Yanmar). The electric fuel solenoid was missing, but an adjustment was all that was needed to get the stock Yanmar manual fuel shutoff mechanism working again.

It looks like this unit was in the middle of an incomplete Yanmar repower. It was an MEP-701A, not an MEP-016A, and the Yanmar is an L100, not the smaller L70. The muffler was loose and the exhaust gasket was with the unit but not installed. The fuel return line was there but not connected. The motor looks new. I pulled the valve cover to inspect and everything inside looked new.

I still have to go through the wiring and see what is not needed since it will be manual start.

I thought about converting the unit to 12V electric start (new 12V starter and battery) but it looks like the gen head gets 24V from the motor to feed the field circuit. I think it could be done with a 12V/24V regulator but I'd rather not have to install/maintain a battery if it isn't necessary.

flatdog555

New member

- 17

- 0

- 1

- Location

- West Linn, Oregon

I haven't been able to pull start mine yet, but it runs great. Mine is really stiff, and I moved it about a foot across the ground when I tried to give it a yank. Until I read your post, I thought the rope start was a joke they played on the new guy.

If you get a chance, could you check out the wiring on your generator to see what the windings actually are connected to? Mine doesn't output power, and my wiring ohmed out T1 to T5, T2 to T6, and T3 to T4. This doesn't match any manual I could find, or the wiring diagram under the lid.

If you need any pictures of what's supposed to be on an MEP-016E, I could take some pictures of mine...

It looks like they removed the speed adjust and used a big set screw instead that has been hard wired after being set. Other than that, mine appears to be complete after a "reset" at Ft. Hood, Texas where they kept the frame and gas tank and replaced everything else. Looks great, doesn't generate.

Thanks,

Flatdog555

If you get a chance, could you check out the wiring on your generator to see what the windings actually are connected to? Mine doesn't output power, and my wiring ohmed out T1 to T5, T2 to T6, and T3 to T4. This doesn't match any manual I could find, or the wiring diagram under the lid.

If you need any pictures of what's supposed to be on an MEP-016E, I could take some pictures of mine...

It looks like they removed the speed adjust and used a big set screw instead that has been hard wired after being set. Other than that, mine appears to be complete after a "reset" at Ft. Hood, Texas where they kept the frame and gas tank and replaced everything else. Looks great, doesn't generate.

Thanks,

Flatdog555

To pull start:

1. Slowly pull the rope until extreme resistance is felt. This will happen when it reaches compression stroke. Let the rope back in.

2. Flip the red decompression lever on the top of the cylinder head.

3. Give a good, strong, long tug on the rope.

My windings are as per manual: T1-T4. T2-T5, and T3-T6.

Do you have the TM 5-6115-615-34 maintenance manual for the 016B?

It contains troubleshooting guidelines.

You probably have a bad VR.

But, it could be field or diode related, too.

PM me you email address if you don't have all three 016B TMs. I also have civilian manuals for the Yanmar L-100.

I haven't seen a 016E manual, yet. Let me know if you know where I can find one in PDF.

1. Slowly pull the rope until extreme resistance is felt. This will happen when it reaches compression stroke. Let the rope back in.

2. Flip the red decompression lever on the top of the cylinder head.

3. Give a good, strong, long tug on the rope.

My windings are as per manual: T1-T4. T2-T5, and T3-T6.

Do you have the TM 5-6115-615-34 maintenance manual for the 016B?

It contains troubleshooting guidelines.

My meter (Fluke 87) gave me higher Ohm reading than the manual specified. I think I got like 60Ohms on the field winding where the manual called for 27. I haven't made power, yet, but I think the winding is OK.ENGINE RUNS NORMALLY, BUT GENERATOR HAS NO OUTPUT.

Step 1. Check voltage regulator.

Step 2. Check exciter field (stator) for open or shorted windings.

Etc., Etc.

You probably have a bad VR.

But, it could be field or diode related, too.

PM me you email address if you don't have all three 016B TMs. I also have civilian manuals for the Yanmar L-100.

I haven't seen a 016E manual, yet. Let me know if you know where I can find one in PDF.

flatdog555

New member

- 17

- 0

- 1

- Location

- West Linn, Oregon

derf,

Thanks for the reply in both articles. Mine appears to have been in the middle of a re-power as well. I'm missing the entire shutdown solenoid and the speed adjust cable. There is the addition of a small cylinder that takes the two wires that used to go to the solenoid and make it into 3 wires. The cylinder is about 5" long, and about 3/4" in diameter. It's potted inside, so I can't see what's in it, but I think it is meant to allow connection of the old 2 wire solenoid that had an internal switch to change between the pull-in coil and the holding coil in the solenoid.

The little cylinder is marked "made in China". Not the best of plans to have your replacement parts made by somebody that you may not always be on good terms with in the future?

Mine didn't even have the original Yanmar shutdown mechanical assembly on it, just the governor shaft sticking out with a bellcrank welded to it. It does have a big set screw on the bottom which allows a spring-backed plunger to engage the bellcrank. I bought a solenoid off of ebay, and am designing a new linkage so that my shutdown works from the front switch instead of using the compression release to shutdown everything.

It was kind of a surprise the first time I had it running. When I switched the knob from "run" to "stop" and nothing happened...

I used your method of pull starting, and it took a couple of tries to get it going, but it did start with the pull rope. If you get a chance and could post a picture of your Yanmar mechanical shutdown, I would really appreciate it. Mine is bald.

Also, I may be interested in your ASK panels. I haven't decided on whether to leave it open for cooling, or close it up for noise yet. I'm in Oregon, so shipping may be an issue. I know you're missing one of the panels, but that might not be too hard to make. I have a full machine shop at my disposal with water-jet and laser cutter as well as lathes and CNC mills.

Thanks,

Ed (flatdog555)

Thanks for the reply in both articles. Mine appears to have been in the middle of a re-power as well. I'm missing the entire shutdown solenoid and the speed adjust cable. There is the addition of a small cylinder that takes the two wires that used to go to the solenoid and make it into 3 wires. The cylinder is about 5" long, and about 3/4" in diameter. It's potted inside, so I can't see what's in it, but I think it is meant to allow connection of the old 2 wire solenoid that had an internal switch to change between the pull-in coil and the holding coil in the solenoid.

The little cylinder is marked "made in China". Not the best of plans to have your replacement parts made by somebody that you may not always be on good terms with in the future?

Mine didn't even have the original Yanmar shutdown mechanical assembly on it, just the governor shaft sticking out with a bellcrank welded to it. It does have a big set screw on the bottom which allows a spring-backed plunger to engage the bellcrank. I bought a solenoid off of ebay, and am designing a new linkage so that my shutdown works from the front switch instead of using the compression release to shutdown everything.

It was kind of a surprise the first time I had it running. When I switched the knob from "run" to "stop" and nothing happened...

I used your method of pull starting, and it took a couple of tries to get it going, but it did start with the pull rope. If you get a chance and could post a picture of your Yanmar mechanical shutdown, I would really appreciate it. Mine is bald.

Also, I may be interested in your ASK panels. I haven't decided on whether to leave it open for cooling, or close it up for noise yet. I'm in Oregon, so shipping may be an issue. I know you're missing one of the panels, but that might not be too hard to make. I have a full machine shop at my disposal with water-jet and laser cutter as well as lathes and CNC mills.

Thanks,

Ed (flatdog555)

I have 4 of the 6 ASK panels. I had a guy who wanted them but I haven't heard from him lately. I had to dig up a box that they would fit in. I'll email him.

Mine just had the mechanical shutdown disabled with a tab under a screw that held the catch back. The solenoid would then only have to push the lever over to the right for run and release and let the spring move it left for shutdown.

My Yanmar shutdown mechanism is just like the stock mechanism on Yanmars and China 186 Diesels. The China 186 is a clone of the Yanmar and I'm told many parts will interchange. Also, I think the mechanism is the same for all the L series Yanmars, 4-10HP.

You set the lever in run position by moving it left to right and it catches. You hit the stop lever and it releases the run lever and allows it to spring back left. I plan to install a remote cable to operate the stop lever. Cable attaching points are already made into the mechanism. I have a solid "choke" style cable that should work.

I've considered making a linkage to use the speed control cable. I probably won't, though. Most commercial gens don't have Freq meters and fine adjustments so they aren't totally necessary, IMHO. They are nice, but most things don't care if they get exactly 60Hz. I'll keep the meter, though. I may fab up a more friendly adjustment knob at the governor to make it adjustable by hand. Maybe something big and knurled with a spring to keep it from wandering.

Mine just had the mechanical shutdown disabled with a tab under a screw that held the catch back. The solenoid would then only have to push the lever over to the right for run and release and let the spring move it left for shutdown.

My Yanmar shutdown mechanism is just like the stock mechanism on Yanmars and China 186 Diesels. The China 186 is a clone of the Yanmar and I'm told many parts will interchange. Also, I think the mechanism is the same for all the L series Yanmars, 4-10HP.

You set the lever in run position by moving it left to right and it catches. You hit the stop lever and it releases the run lever and allows it to spring back left. I plan to install a remote cable to operate the stop lever. Cable attaching points are already made into the mechanism. I have a solid "choke" style cable that should work.

I've considered making a linkage to use the speed control cable. I probably won't, though. Most commercial gens don't have Freq meters and fine adjustments so they aren't totally necessary, IMHO. They are nice, but most things don't care if they get exactly 60Hz. I'll keep the meter, though. I may fab up a more friendly adjustment knob at the governor to make it adjustable by hand. Maybe something big and knurled with a spring to keep it from wandering.

flatdog555

New member

- 17

- 0

- 1

- Location

- West Linn, Oregon

Thanks,

I took a look at both the Yanmar, and as soon as you said China 186, the whole world opened up. Seems like every engine company in China is copying every other engine company, so there are lots of choices for parts. I bought one of the shutdown solenoids off of ebay, and pretty much have a design for the linkage (that uses fewer parts than came originally). I think for the speed adjust, I'll just put a small knob on the end of the set screw adjustment so that I can set it close to 60 if I have a bigger or smaller load. For the most part 57 to 63 Hz works fine, not that I care if a clock gains or loses time, I'm not using the generator that often. If I can run the furnace fan and the well and a couple of lights, I'm a happy guy. Let me know if that guy doesn't want the ASK panels, I may be interested.

Thanks,

Ed (flatdog555)

I took a look at both the Yanmar, and as soon as you said China 186, the whole world opened up. Seems like every engine company in China is copying every other engine company, so there are lots of choices for parts. I bought one of the shutdown solenoids off of ebay, and pretty much have a design for the linkage (that uses fewer parts than came originally). I think for the speed adjust, I'll just put a small knob on the end of the set screw adjustment so that I can set it close to 60 if I have a bigger or smaller load. For the most part 57 to 63 Hz works fine, not that I care if a clock gains or loses time, I'm not using the generator that often. If I can run the furnace fan and the well and a couple of lights, I'm a happy guy. Let me know if that guy doesn't want the ASK panels, I may be interested.

Thanks,

Ed (flatdog555)

rivercreek

Member

- 101

- 1

- 18

- Location

- Berryville, VA

I know this is an old post, but I've got an 016E and I'm having issues with the throttle solenoid as well. What I'm trying to find out is the purpose of the additional electronics below the fuel filter housing ? I'm wondering if it has automatic throttle control ? If not, how do you fine tune HZ without being able to fine tune RPM's ? Any insight would be helpful. Thanks!

Additional stuff in fuel pump wiring should be RF filters which are not necessary.

You should be able to fine tune the RPM and Hz with the throttle control. Either the knob below the control box or some kind of adjustment on the governor should facilitate RPM adjustment. I'll have to look when I get home as I can't remember the differences between the Es and Ds right now.

You should be able to fine tune the RPM and Hz with the throttle control. Either the knob below the control box or some kind of adjustment on the governor should facilitate RPM adjustment. I'll have to look when I get home as I can't remember the differences between the Es and Ds right now.

ETN550

New member

- 457

- 9

- 0

- Location

- Knoxville, TN

The stuff below the fuel filter is as follows:

2 small identical relays side by side are for the grid heaters. All incoming and outgoinjg wires are split so each relay coil and relay contact sees half the load. Strange.

The large cylindrical unit with the hoses is the primary fuel pump that takes fuel from the tank and pushes it through the filter to the injection pump.

The square block in the wiring for the fuel pump is an RF suppressor.

The long cylindrical piece has something to do with the fuel control solenoid. Two wires come in but three go to the solenoid.

The speed or frequency is no longer adjustable from the panel. The adjustment is made by screwing the solenoid plunger in and out making it shorter or longer. There is a small locknut to loosten and the long barrel nut can be held while the flats on the backside of the plunger can be turned. I just had one in that needed adjusting and although it looks kind of hokey one full turn is less than one Hz so it is pretty easy to get set accurately with a few tries.

A note on cooling these engines in the 701A housing. I believe converting the enclosed 701A to Yanmar was a mistake. The Onan discharged its cooling air out the top and was designed to do so from the start. The Yanmar does not so the hot air off the head and cylinder gets trapped in the housing and recirculated causing overheating. Witness the huge number of 016Es that have a frame with the inserts to take the 701A enclosure but have no enclosure. I believe that the military eventually stripped off the enclosure when adding the Yanmar. I have studied some enclosed units with Yanmar. My latest is a pump. Runs very quiet and has a sheild inside so the fan intake around the recoil starter cannot pull hot air. So I conclude that to properly use the Yanmar in the 701A enclosure there needs to be modifications so the engine and generator fan intakes are only sucking cool air. Then I think it would work. Might try this mod myself if I ever have enough time.

Also, if anyone is interested I just completed my 4th generation battery tray to convert the single 24 volt 4HN battery to Two 12 volt lawn and garden tractor batteries. This latest version will fit the two batteries inside the existing 701A enclosure with a small modification. I can post up some pics if interested. Several advantages to Two 12volt batteries. (Under $30 each, more total amps possible, Jumper wire disconnect allows charging with 12volt charger, batteries very available at any auto store or walmart. I bought 11 batteries for $21.95 ea at Advance Auto. they had a sale in March - April. I'm thinking of offering conversions if interested. I have converted 11 total so far. 016B, 016E and 701A.

2 small identical relays side by side are for the grid heaters. All incoming and outgoinjg wires are split so each relay coil and relay contact sees half the load. Strange.

The large cylindrical unit with the hoses is the primary fuel pump that takes fuel from the tank and pushes it through the filter to the injection pump.

The square block in the wiring for the fuel pump is an RF suppressor.

The long cylindrical piece has something to do with the fuel control solenoid. Two wires come in but three go to the solenoid.

The speed or frequency is no longer adjustable from the panel. The adjustment is made by screwing the solenoid plunger in and out making it shorter or longer. There is a small locknut to loosten and the long barrel nut can be held while the flats on the backside of the plunger can be turned. I just had one in that needed adjusting and although it looks kind of hokey one full turn is less than one Hz so it is pretty easy to get set accurately with a few tries.

A note on cooling these engines in the 701A housing. I believe converting the enclosed 701A to Yanmar was a mistake. The Onan discharged its cooling air out the top and was designed to do so from the start. The Yanmar does not so the hot air off the head and cylinder gets trapped in the housing and recirculated causing overheating. Witness the huge number of 016Es that have a frame with the inserts to take the 701A enclosure but have no enclosure. I believe that the military eventually stripped off the enclosure when adding the Yanmar. I have studied some enclosed units with Yanmar. My latest is a pump. Runs very quiet and has a sheild inside so the fan intake around the recoil starter cannot pull hot air. So I conclude that to properly use the Yanmar in the 701A enclosure there needs to be modifications so the engine and generator fan intakes are only sucking cool air. Then I think it would work. Might try this mod myself if I ever have enough time.

Also, if anyone is interested I just completed my 4th generation battery tray to convert the single 24 volt 4HN battery to Two 12 volt lawn and garden tractor batteries. This latest version will fit the two batteries inside the existing 701A enclosure with a small modification. I can post up some pics if interested. Several advantages to Two 12volt batteries. (Under $30 each, more total amps possible, Jumper wire disconnect allows charging with 12volt charger, batteries very available at any auto store or walmart. I bought 11 batteries for $21.95 ea at Advance Auto. they had a sale in March - April. I'm thinking of offering conversions if interested. I have converted 11 total so far. 016B, 016E and 701A.

Last edited:

rivercreek

Member

- 101

- 1

- 18

- Location

- Berryville, VA

Thanks very much for that concise info. My 701A / 016E does not have the throttle knob present on the 016B's. Throttle solenoid is threaded for one, but it isn’t there. That fact, coupled with the fact that there are 3 wires instead of two going to the throttle solenoid coming from the little cylindrical mystery part next to the two relays led me to suspect that perhaps it had an automatic throttle control of some kind. Also, there is a small L bracket screwed in to throttle solenoid bracket that locks out the manual shut off, disallowing the detent if that makes sense. Basically the L bracket holds the manual lever fully down in the “stop” position. I felt there were only two logical reasons for this, 1 being that it had an automatic throttle control, rendering the detent useless or 2 that the bracket was there perhaps for shipping purposes to disallow it to be started. I have the TM’s for the 016B’s, but of course they don’t have the second fuel pump or the cylindrical mystery part. With that said, perhaps you have a solution right off the top of your head for my current problem. Story as follows: At about the 48hr point of our current and yes still ongoing power outage from Friday night’s storm, I loaded up the 701A /016E and took it over to a neighbor’s house. After wiring it up to his panel, I pull started it (battery dead as a doornail) and she fired right up. Let her warm up a minute or two, threw the main and power was had by all. Hoots, hollers, backslapping, wives shrieking with delight, etc. App. 5 minutes after starting unit, she shut down just like I hit the switch. DC breaker had blown. Reset, restart, almost immediately blew – releasing throttle solenoid and therefore shutting down. Unit would start and run with breaker blown (I did that only momentarily, but several times) and produce AC power – but I was afraid to remove the L bracket and just set the throttle to the detent and let her run for fear of burning something up. I read that perhaps it could be a bad fuel pump and I’ve yet to check that. I will say that the next day, I went back over to give it another try and couldn’t get it to fire pull starting it. After removing top of fuel filter housing, found fuel app. 1” below top. I topped it off, bled it, and she fired up. Still blew DC breaker almost immediately. The power is STILL out here in Doddridge County, WV (I’m out at my Mom’s place if you were curious why my profile says I’m from Leesburg, VA) and we’re told not to expect any power until Sunday. I’m hoping to get this thing going to give my poor neighbor some relief if I can. . I believe that’s all the pertinent facts – any ideas or even theories would be very welcome. Thanks again.

rivercreek

Member

- 101

- 1

- 18

- Location

- Berryville, VA

Thanks very much for that concise info. My 701A / 016E does not have the throttle knob present on the 016B's. Throttle solenoid is threaded for one, but it isn’t there. That fact, coupled with the fact that there are 3 wires instead of two going to the throttle solenoid coming from the little cylindrical mystery part next to the two relays led me to suspect that perhaps it had an automatic throttle control of some kind. Also, there is a small L bracket screwed in to throttle solenoid bracket that locks out the manual shut off, disallowing the detent if that makes sense. Basically the L bracket holds the manual lever fully down in the “stop” position. I felt there were only two logical reasons for this, 1 being that it had an automatic throttle control, rendering the detent useless or 2 that the bracket was there perhaps for shipping purposes to disallow it to be started. I have the TM’s for the 016B’s, but of course they don’t have the second fuel pump or the cylindrical mystery part. With that said, perhaps you have a solution right off the top of your head for my current problem. Story as follows: At about the 48hr point of our current and yes still ongoing power outage from Friday night’s storm, I loaded up the 701A /016E and took it over to a neighbor’s house. After wiring it up to his panel, I pull started it (battery dead as a doornail) and she fired right up. Let her warm up a minute or two, threw the main and power was had by all. Hoots, hollers, backslapping, wives shrieking with delight, etc. App. 5 minutes after starting unit, she shut down just like I hit the switch. DC breaker had blown. Reset, restart, almost immediately blew – releasing throttle solenoid and therefore shutting down. Unit would start and run with breaker blown (I did that only momentarily, but several times) and produce AC power – but I was afraid to remove the L bracket and just set the throttle to the detent and let her run for fear of burning something up. I read that perhaps it could be a bad fuel pump and I’ve yet to check that. I will say that the next day, I went back over to give it another try and couldn’t get it to fire pull starting it. After removing top of fuel filter housing, found fuel app. 1” below top. I topped it off, bled it, and she fired up. Still blew DC breaker almost immediately. The power is STILL out here in Doddridge County, WV (I’m out at my Mom’s place if you were curious why my profile says I’m from Leesburg, VA) and we’re told not to expect any power until Sunday. I’m hoping to get this thing going to give my poor neighbor some relief if I can. . I believe that’s all the pertinent facts – any ideas or even theories would be very welcome. Thanks again.

rivercreek

Member

- 101

- 1

- 18

- Location

- Berryville, VA

Sorry about that. Hit the wrong buttons.

ETN550

New member

- 457

- 9

- 0

- Location

- Knoxville, TN

To bypass the solenoid at the fuel lever you may remove the little L bracket that prevents the throttle lever from latching. To adjust the set speed when using the latching lever loosten the two bolts that hold the throttle lever to the engine case. the left bolt is a pivot bolt, the right one is in a slot. rotate the assembly clockwise for more speed and ccw for less. then tighten the bolts.

You may be running with a failed pump and draining the top inch of the filter housing. The fuel goes out of the filter housing through a small hole in the side of the center bolt an inch or so below the top of the housing.

If you have a the aux fuel pump on the side of the unit at the bottom by the tank it can be swapped in place of the main pump. they are the same but you will need to swap over the fittings too.

There is a problem with these main pumps. I was about to start a thread on it. I have now had 3 of 3 facet pumps fail on three different 016E. Some are shorted and trip the breaker some draw current do not trip the breaker but do not pump. They are all the new ones supplied with the conversion to Yanmar. I suspect either 1) a manufacturing flaw in later versions, or 2) they do not like to be dead ended as they are on the Yanmar. I'm going to run a unit with the aux pump in place of the failed facet main pump and see if it eats up the aux pump as well. It would be very easy to tee in a small diameter fitting and line which would run from the injector pump feed line after the filter to the injector leakoff line. then the pump would always move fuel and stay cool. This is how these pumps operate in everyother environment. They are bullet proof on the 002a's and 003a's. so why not on the "E"?

The Yanmar injection pump will take any gravity feed just fine. Just make sure the line to the injection pump has no upward slope in it or else trapped air cannot move up the line and purge itself.

To run for the outage make the throttle latch and adjust rpm to 60Hz and gravity feed the injection pump or replace it with the existing aux pump.

Once you unplug the bad pump or swap over the aux pump the breaker will stop tripping if it is the pump that was bad.

good luck!

You may be running with a failed pump and draining the top inch of the filter housing. The fuel goes out of the filter housing through a small hole in the side of the center bolt an inch or so below the top of the housing.

If you have a the aux fuel pump on the side of the unit at the bottom by the tank it can be swapped in place of the main pump. they are the same but you will need to swap over the fittings too.

There is a problem with these main pumps. I was about to start a thread on it. I have now had 3 of 3 facet pumps fail on three different 016E. Some are shorted and trip the breaker some draw current do not trip the breaker but do not pump. They are all the new ones supplied with the conversion to Yanmar. I suspect either 1) a manufacturing flaw in later versions, or 2) they do not like to be dead ended as they are on the Yanmar. I'm going to run a unit with the aux pump in place of the failed facet main pump and see if it eats up the aux pump as well. It would be very easy to tee in a small diameter fitting and line which would run from the injector pump feed line after the filter to the injector leakoff line. then the pump would always move fuel and stay cool. This is how these pumps operate in everyother environment. They are bullet proof on the 002a's and 003a's. so why not on the "E"?

The Yanmar injection pump will take any gravity feed just fine. Just make sure the line to the injection pump has no upward slope in it or else trapped air cannot move up the line and purge itself.

To run for the outage make the throttle latch and adjust rpm to 60Hz and gravity feed the injection pump or replace it with the existing aux pump.

Once you unplug the bad pump or swap over the aux pump the breaker will stop tripping if it is the pump that was bad.

good luck!

Last edited:

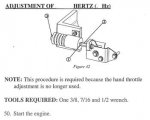

Here are some instructions on Hz adjustment:

Attachments

-

13.2 KB Views: 30

Last edited:

- 114,103members

- 167,071threads

- 2,352,245posts

- 2,782online users