- 9,576

- 210

- 63

- Location

- Dickson,TN

I'm trying to get my winch back together after replacing all the seals. I took the winch apart about a year ago so it's kind of fuzzy on where all the parts go back.

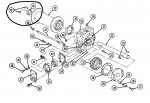

The problem is a thrust washer (part number 2286131, item 31 on page 35 of TM9-3830-206-34P). TM9-3830-206-34P shows the washer to go between the worm gear housing and the drum. When I put the washer in this position it seems the drum isn't going against the worm housing far enough (it's hitting the thrust washer). Could the TM be wrong on the location of the washer because there doesn't seem like there's enough space for it where it is.

The problem is a thrust washer (part number 2286131, item 31 on page 35 of TM9-3830-206-34P). TM9-3830-206-34P shows the washer to go between the worm gear housing and the drum. When I put the washer in this position it seems the drum isn't going against the worm housing far enough (it's hitting the thrust washer). Could the TM be wrong on the location of the washer because there doesn't seem like there's enough space for it where it is.