- 10,350

- 75

- 48

- Location

- Meadows of Dan, Virginia

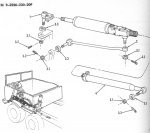

The other day I put the front axles on blocks, removed the wheels/tires and started to exercise the steering.

Turning the steering wheel was still kind of tough and I'm wondering about the "sealed for life" joints, perhaps a dozed or so in this mechanism.

These kind of joints must be used in the general automotive industy and what is the long term experience with them, as in not used for a long time? Any experts out there?

Turning the steering wheel was still kind of tough and I'm wondering about the "sealed for life" joints, perhaps a dozed or so in this mechanism.

These kind of joints must be used in the general automotive industy and what is the long term experience with them, as in not used for a long time? Any experts out there?

Attachments

-

183.4 KB Views: 1,329

-

143.2 KB Views: 1,327