2-89-4. Adjustment

a. Shut down generator set.

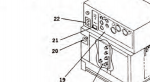

b. Open left side engine access door and remove control cable wedge (2, Figure 2-24) from governor speed lever

(3).

c. Loosen jam nuts on both speed adjust bolts on governor control and turn bolts counterclockwise until they do

not touch speed lever (3).

d. Adjust frequency control adjust cable (6) with nuts (4) and (7) and connect cable to speed lever (3) so that lever

is positioned approximately mid-range.

e. Start generator set. Using frequency adjust control, adjust frequency to 65 Hz (420 Hz for MEP-812A).

f. Turn high speed adjust bolt on governor control until it contacts speed lever (3) and tighten jam nut

g. Using frequency adjust control, adjust frequency to 58 Hz (388 Hz for MEP-812A)

h. Turn low speed adjust bolt on governor control until it contacts speed lever (3) and tighten jam nut

i. Using frequency adjust control, cycle generator set frequency from minimum to maximum and back to minimum

to verify settings.

j. Readjust high or low speed adjust bolts on governor control as needed to obtain required frequency adjustment

range.