So when I removed the fuel pump, I had to pull the power steering pump as well.

I removed the PS pump leaving the adaptor attached to the lube pump. ( Like the TM says to do!)

The PS pump would not clear the fuel pump so I massaged it a bit and clearanced it.

The PS Pump comes out from the top on an M916 .

So when I pulled the PS pump that splined coupling inside the adaptor falls off the lube pump so not

wanting to err I pulled the adaptor off too.

All fine and dandy. But now in wanting to do things right I look at the TM and it says

to R&R gasket/o-ring #27 ! But WAIT! When I pulled the PS pump off the adaptor

there WAS NO SUCH ORING, and as the TM shows, no gasket between the adaptor

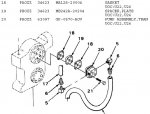

and PS pump as well, it was steel to steel! ! Uggh! So when you go to the -24 Parts TM you can clearly

see that "Gasket / O-Ring" Part 33 listed w/ the P/N 008771-026 . (UNOBTAINIUM!)

( The the top 2 pics below)

So I called Cummins, no joy, that is not a Cummins P/N for that O-Ring!

OK, next I tried to determine the Model and Mfg of the PS pump.

I do a lil searching and I find the following;

_____________________

2530-01-074-2917 Power Steering Pump. Eaton ER15867-1. AM General MD253-20001. Fits M915. Verify you application.Invoice on this assembly is $953.00, 14968 R2C11

dpequip.net

You are buying a brand new 2530-01-074-2917 Power Steering Pump. Eaton ER15867-1. AM General MD253-20001. Fits M915. Verify you application.Invoice on this assembly is $953.00, Get it here and save some money! We ship FAST ! 14968 R2C11

_____________________

OK I write Eaton (Haldex) and Tech support and I determine that if I buy PS Pump

rebuild kit #R3307 that kit should have the oring I need.

R3307 by HALDEX - Power Steering Pump Seal Kit (finditparts.com)

The 3rd from top pic below shows what I THINK I want...

In the bottom pic, from another TM, you see PN #27 that is the same as #33 I believe.

You see no gasket between adaptor and ps pump again as well. TM says use RTV...

I am inclined to forget the O-Ring and just use some Permatex Black Make a gasket and call it done.

Wes or anyone , do you have any input?