bushhawg73

Member

- 122

- 0

- 16

- Location

- Columbia, Missouri

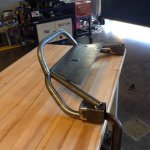

The way this mount is secured is with bolts. Basically if your standing over it looking down there is a bolt that goes through the truck frame extender and then through the winch bracket or mount. Its not a lock but it would take some time to unbolt. The bolts also help steady up the mount so there is no up and down wiggle. Makes it a real secure unit. The clevises hold it in place while the bolts are secured and then she is rock solid. I think you can see the bolt holes in one of the mount pics I posted.Hi!, I had planned on putting one set of "mounts" on top of the winch plate, similar to yours, and one set on the bottom side.

Do you know if the outside demensions on the square tubing you used would allow a padlock to be placed through the holes on one side if you wanted to keep it mounted?

I'm thinking one of those good quality round style master locks, if it fits it would be very hard to get a set of cutters on Id think, but maybe not.

Look at reply #30. the hole that has the washer outline on it is the hole we use to bolt it in place.