Use one of the ignition controlled 12v spots on the left side of the fuse box. You should have 2 or 3 free ones. They are single spade, non fused, so make sure you add an inline fuse.

I was hoping to find a wire in the engine compartment to save going through the fire wall... i think I'd have to pull the fuse box off, run the wire through the firewall, and tap it in the back of the fuse box to do what you are suggesting... or could I just add it to the connector? Please let us know here!

I'm sure that is solid advice... but a bit beyond my experience level. I never have pulled a fuse box apart so I didn't even consider it! Seeing I really wanted to finish this one and move on, yesterday afternoon I traced out the various wires using the -34 scematcis.... E-4 through e_9 if I recall correctly... and decided to splice it into the Pink/BLack wire that sends power to the water in fuel sensor amoung a few other sensors... figured if I screwed that circuit up the consequences would be minimal...

But I suspect Lavarok's suggestion above is far superior.

I tapped in where the bundle comes through the firewall near the back of the fuse panel, but looknig back it would have been an easier and shorter run if I would have just hit the pink/black water in fuel wire near the fuel filter housing. (I ran the wire right up below the NEG/GND buss bar and tied it in there right on the buss with a large ring terminal, then ran up over the glow plug resister and down to the fuse box bundle)

ETA: Looking back I wished I'd tied on to this pink black line (faded it looks more orng/black) near the standadine square fuel filter... connecting there would have been easier and required less wire... on my civie 6.2 suburban the standadine was replaced with a spin on a long time ago and the wires were there unused... easy patch in...

Still looking to make this a good standard well though out mod for hobbiest newbies like myself!

Oh and to summarize the physical install of the Airtex 8153 kit (comes with two metal hose barb nipples, hose clamps, two 18 Ga butt splicers, & two ~3" sections of 3/8 fuel hose... though the instructions specify using 14Ga wire & the leads off the pump are 18GA )and a Fram G3 type 3/8" inline filter:

We (my friend 'Shade_Tree' did most of the work) cut the rubber fuel line near the muffler where it goes from inside the frame rail to the top outside, and used a siphon to start it draining down an extra piece of fuel line as I just got the truck an didn't know what was in the tank.... we got about 7 gallons out and found all the fuel to be bright and clear, so we stuffed an air gun up to the hose, blew air up to stop the siphon and started the install of the electric fuel pump and pre filter.

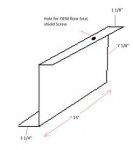

Shade_Tree decided to move the fuel return line and break line up to the top hole, and squished the large OEM retainer to hold them separately. This took a bit of coaxing on the hard pipe, but nothing that came close to making a kink. Doing that let us use the lower hole for the pump and it held it perfectly just off the bottom of the frame rail with a very slight upward tilt. Shade_Tree cut back the large middle solid tube that went over the frame rail (the supply tube) back towards the tank by removing the bolts that held it on the rail and then used a small pipe cutter. To clean up the burs we then used a counter sink on a drill to ream the inside a slight bit and a file to clean the outer burs... this put the cut higher than the intake of the pump and allowed the pre filter to have the upward slope to mininize air pockets... seeing there was no barb on the pipe we slid the 3/8 hose up it about 3" and used two screw type hose claps to be doubly sure of a good seal.

To make an install of the pre-filter truly vertical in such a tight space, we couldn't see how to do it with out buying pre made 3/8 inch 90's. But this seems like a very good compromise: When the electric pump is running it pulls all the air out and there are zero air pockects. the mech pump pulls fuel through the filter and pump at idle just fine but does have a very small airpocket in the filter (see pic).

My mercedes 240D has a small inline prefilter was well along with a hand priming pump mounted to the block... i've never had 0 airbubles in it except when it starts to clog and then it will begin to fill all the way with fuel as the part of the screen that was submerged starts to clog.

Next is finding a good fitting to bypass the mech pump (so I can reinstall it if I want... or a EMP kills my electric pump

) Looking for help there too. See red arrow on B&W graphic below... though the graphic shows a male end... the CUCV pump has a female fitting on it... so the bypass will need a female end of the same thread and size.

Also need to make a heat shield to protect the filter and pump from the exhaust that they are so close to.

Materials list thus far:

--Airtex - Diesel Electric Fuel Pump Kit, Part Number: E8153 $60

--Fram G3 or equiv 3/8 inline fuel filter $4

--Electrical Tape: (on hand)

--10' small black conduit: $10

--20' black/yellow AWG 14 automotive wire: $10

--Zip ties (on hand)

--Blue electric wire taps $5

--Multi-pack Butt Splicers $10

--Weather tight fuse holder $5

--Large ring terminal: (on hand)

--10A micro fuse (on hand)

--4' 3/8" fuel line $4 (only needed a foot so far) $8

--hose clamps (on hand)