rustystud

Well-known member

- 9,402

- 3,392

- 113

- Location

- Woodinville, Washington

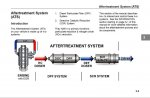

View attachment Scan0205.pdfView attachment Scan0206.pdfModern diesel engine DO put unburnt fuel directly into the exhaust, be it into the pipe just past the outlet of the turbo via separate injector or via 5th injection (dosing) cycle when the exhaust valve is open and evacuating the cylinder of the burnt gasses, That is how the catalyst starts the reaction needed to get the DPF inlet to the required temp to turn the soot to ash, don't care if it is Cat, Cummins, Navistar, Volvo, Mack, Isusu, Deere, Ford, VW, they ALL hydrocarbon dose the aftertreatment to start the process.

The above switch completes a circuit when the throttle is released (at idle position) that allows DC voltage to energize the EB solenoids, it doesn't shut fuel off, drive by wire engines use the TPS to send that signal.

Again there is a grain of truth to your statement, but the reality is something different. The system your describing is the "Lean NOx catalyst" system. It is only used on a very few engines. The most common is the "SCR" system which uses the "urea" solution. That is the stuff you must add to almost every modern diesel engine on the road today. Your comment about the switch is also misleading. Of course the engines ECM controls the fuel but it receives the signal to shut-off from the Jake brake. So I have a question for you Mr. Wagner. Have you ever actually worked on a Jake brake system ? I can assure you I have, plenty of times. So again I'm speaking from personal experience here. If you can provide technical proof that I'm full of "Sh!t" then I will graciously admit I'm wrong to the whole Steel Soldiers community. As they say "the ball is in your court" .