Shifting problem appears to be solved!  I r

I replaced the vacuum modulator this afternoon, and the shift points finally moved. After removing the old vacuum regulator, upon closer inspection it looks like there was some gunk in the end that connects to the hose/hard line. Since the trans was shifting/working fine prior to the flexplate replacement, my best guess is that I got the end of the hose dirty when I pushed it out of my way, and then introduced some contaminants into the modulator when I reconnected it.

On my short test drive the transmission shifted so low and soft that I didn't even notice it shifting from 1->2 the first time (

swiveled the vacuum regulator all the way towards the firewall at last adjustment a few days ago, in a last ditch effort to get the points to budge lower). Now the shift points with the new modulator and new regulator (s

wiveled all the way towards the firewall) are around 10 & 20. These are too low IMO, so tomorrow when I have time to do the adjust/test-drive/adjust routine I'll increase them to around 15 and 30.

Also the shift points are very soft... barely noticeable. Maybe they will harden up when I increase the shift points to 15 & 30, but I also read that there is an adjustment tab within the vacuum modulator that can make the shift points harder/softer

. @ezgn you mentioned that previously in this thread that I don't want soft shift points. Can you elaborate? I always assumed hard shifting was a sign of a transmission trouble, and that soft shifting was a sign of a healthy trans.... but I also know next to nothing about transmissions and am only a few years into getting to know my CUCV.

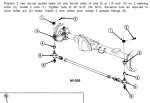

Lastly, I also had time to replace the pitman-to-axle drag links, the drag link adjustment sleeve, and the steering stabilizer today with new Moog parts from Advanced Auto. Also rotated the tires. Only had time for about a half-mile test drive afterwards, but steering was

significantly tighter and I didn't notice a bit of wobble! Will go for a longer test drive tomorrow to verify that it's really improved.

CraneAxle kingpin spring eliminator kit hasn't come in yet, but I plan to install it tomorrow if it gets delivered in time.

I did notice while I was replacing the steering stabilizer that the front (long) drag link is slightly warped/bent. Looks like somebody drove it into a stump or something, and it's put just a slight concave bend in the bar. Should I try to get it straightened out, replace it, or just leave it be?