- 456

- 0

- 16

- Location

- Eustis, Florida

I have 1972 M109 with a C turbo with a Blown head gasket.

Reference Video

www.youtube.com/watch?v=qEIHjNoIeNU

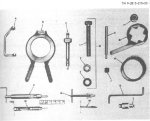

I know there are multiple threads on how to changed the head gasket on a M35A2, however my inquiry today is in reference to the tool that is used to remove the head. I have the TM 9-2320-209-34-2-1 Page 2-42 on how to change the head its self.

Is there a name of the tool or place that i can buy this tool?

I have the Head Gasket Set and upper end gasket kit from Memphis Trucking. I want to start this project on Thursday this week; however I just want to ensure that I have the right tools.

Reference Video

www.youtube.com/watch?v=qEIHjNoIeNU

I know there are multiple threads on how to changed the head gasket on a M35A2, however my inquiry today is in reference to the tool that is used to remove the head. I have the TM 9-2320-209-34-2-1 Page 2-42 on how to change the head its self.

Is there a name of the tool or place that i can buy this tool?

I have the Head Gasket Set and upper end gasket kit from Memphis Trucking. I want to start this project on Thursday this week; however I just want to ensure that I have the right tools.

Attachments

-

65.4 KB Views: 99

-

38.3 KB Views: 105

-

76.4 KB Views: 88

-

66.3 KB Views: 93

-

53 KB Views: 96

-

66.9 KB Views: 104

-

68.2 KB Views: 107