top_prop

Member

- 243

- 8

- 18

- Location

- Suffolk, VA

Well Shade_tree and I finally finished servicing the front wheel bearings and when we did the second one I took pics... please review the TM... this is only meant to serve as a pictoral illustration of the information found there.

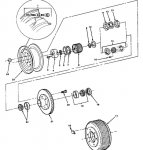

We found the retaining washer for the spindle nuts broken on the front left so I ordered Warn replacement nuts and washer (WARN Manual Hub Spindle Nut Kit 32720) and while I was at it bought premium hubs and put those in as well. I'll sometimes refer to things per their number as in the TM exploded view (figure 97 of -20P) below as well... FYI my m1009 had 19spline hubs....

Again, review the TM... First remove the wheel and then the hub (-20 section 8-3) by removing the six torqs head screws (3) holding it on:

We found the retaining washer for the spindle nuts broken on the front left so I ordered Warn replacement nuts and washer (WARN Manual Hub Spindle Nut Kit 32720) and while I was at it bought premium hubs and put those in as well. I'll sometimes refer to things per their number as in the TM exploded view (figure 97 of -20P) below as well... FYI my m1009 had 19spline hubs....

Again, review the TM... First remove the wheel and then the hub (-20 section 8-3) by removing the six torqs head screws (3) holding it on:

Attachments

-

74.5 KB Views: 580

-

62.8 KB Views: 398

-

66.7 KB Views: 438

Last edited: