Ok, so when you test the 2 connections on the solenoid itself you are getting continuity, meaning the coil in the solenoid is good, which you also confirmed by testing the solenoid with 24V.

Testing the wires I would expect you should get a tone ( continuity ) when testing from battery negative to one of those wires. (K5-2, Wire # P55T16, if the wire # is readable)

If not it sounds like you may have a ground connection issue somewhere.

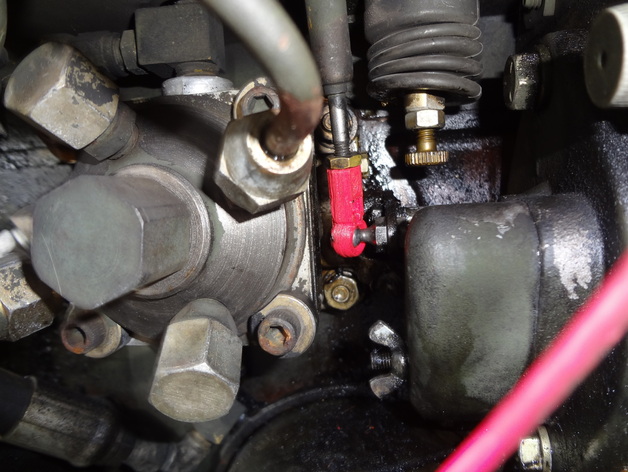

There is a connection on the side of the starter where your negative battery cable attaches to the stud. There are also 2 or 3 smaller wires on that stud.

One of those ( larger ) goes to your slave plug, the smaller goes inside the control cube to the terminal strip.

Check to make sure those connections are all tight.

Check that the connectors on the back of the Control box are all secure ( may want to unscrew and reseat them to ensure good connections )

You can use the wiring diagram to see which position on the terminal block are the grounds. (Should be TB4- 12,13, 14) and where the negative from the fuel solenoid is attached to the terminal block.

Have you checked the 2 solenoid wires to see if you get 24V + when cranking? (This is the key to the problem) That will tell you is you have a ground issue, a power issue or both.