Thanks for the info derf. I will try that when I get time.

It recovers back to normal after I reduce the load. It seems to run like the other as far as the engine goes.

The reason I suspect the fuel system is because the other generator(good) had gunk in the fuel tank valve and inj pump. I cleaned it all out before I started it up. The one I didn't clean is the one acting up. I know I should've cleaned it all out, but...........I was trying to

.........this may be user error

I believe if it was an electrical problem the engine would not drop rpm.

If the engine is producing black smoke when loaded then it is either a dirty air filter or obstruction in the intake (found a shop rag in one once!) or injection timing (unlikely since the pump is shimmed and does not change timing unless someone assembles it wrong) or an injector out of whack.

Try backing out the "smoke" screw. This is the bolt below the fuel lever mechanism that has the plunger coming out of the center of it. adjust it while running. Backing it out will allow more fuel quicker to regain speed after a load application. If it is running and not touching the plunger then someone has already tried that adjustment. In that case proceed to the next step.

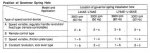

Pull out the manual and verify that the governor spring behind the fuel shutdown and run levers is set to the correct position for a gen application. One end of the spring is in slots or holes marked a, b, c and the other end is in holes 1, 2, 3. there is a table in the manual that tells what the setting is. For example L70 generator 60hz is B2. (just an example, I don't have the book in front of me). They have settings for 50hz so if it is in the wrong position it can mess it up at 60 hz.

While you are looking at the governor spring make sure there is not excess CARC paint on it keeping it from working freely.

Of course the max speed screw can be adjusted if you are not at 60 hz but that screw will not have anything to do with load acceptance.

The above items are the only adjustments available.

But I have one other trick if your getting improvements by adjusting the plunger screw and have run out of plunger travel. If you have backed out the plunger screw and it is not touching the governor lever when the machine is running then manually push the lever into the plunger while it is running and loaded. If it immeadiately picks up speed, and I bet it will, then continue as follows: Pull the governor spring off and measure the center distance with the spring relaxed with some dial calipers. Use needle nose pliers and rotate one end of the spring closed some more so the new center distance is about 0.060" shorter than the original dimension. It does not take very much of a twist at all to make 0.060" difference so be careful. 0.060" will make a world of difference when running and get it back on the plunger bolt for fine adjustment. I do this adjustment from time to time to correct a tired spring. You could buy a new spring. I do not like leaving the engine set with the fuel lever in the run position as it keeps the spring stretched all the time. Also, forcing the lever further may stretch the spring. But the spring may get tired or if there is light corrosion on it it may be a little tired. No big deal to adjust it. The engine is very sensitive to the spring charactoristic as it is the fine sensitivity that allows the engine to maintain precise speed control needed for a gen application.

Now if you are getting black smoke consider having the injector tested and the tip replaced. A diesel shop can do it for about $80.00 including new tip, cleaning the body, reset the opening pressure and putting new gun black on the exterior. Just like new.

I don't think there is anything else it could be. PS. I use the Kill-A-Watt meter to check the 120vac loads and a lot of appliances test less than their nameplate. My 1850 hair dryer is 1630 for example.

Good luck let us know what you find after tinkering some more.

Doug

.........this may be user error

.........this may be user error