Mweiss

Member

- 71

- 49

- 13

- Location

- New Milford, CT

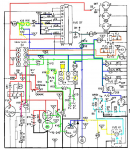

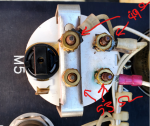

I was in the hospital with stomach cancer when my wife did a video call as I guided her to start the genset and charge the battery bank on a rainy day. She showed me the panel and I knew something wasn't right seeing the fuel gauge not in its customary scale reading. When I got home from the hospital and surgery, I took this picture. A few days later, I opened the panel and measured across the meter terminals. When the start switch is in the fuel pump position, I read 5 volts across this meter, which seems way too high. Most meters are 50mV FS and under. So something happened with the circuit that drives the meter.

When I Google the problem, it's always the opposite--fuel needle pinned to the left. My case seems unusual.

We've been having constant rain and thunderstorms all month, so the generator got at least weekly and sometimes twice weekly use and I hit the 100 hour mark this week and did the oil change. New Wix filter and Shell Rotella Diesel synthetic oil, per recommendations I found elsewhere on the forum. I unscrewed the plug and opened the valve down below. Expected it to pour out like a faucet, but instead, it slowly dribbled out. Took over an hour to drain. Would have taken two hours, but that I found that if I remove the old oil filter and dead crank it a few seconds, another quart would come out very rapidly from the oil filter port. I got two quarts out that way. But wondering why draining oil from these units is so slow? Instead of going into the pan I put under the outlet, it ran down the rails and inside the unit, making a mess that took me 20 minutes to clean up with a lot of paper towels. Hoping I can find a way to improve the flow so it's not so messy next oil change.

Other than the fuel gauge issue, the generator has been putting in yeoman service. And it's a good thing I got it just in time. My Northstar generator, which has been up for sale for 10 months (Honda V-twin engine with 303 hours on the clock) blew a piston ring today while I was running it to maintain it from taking on moisture. Engine sticker says "made in China" so maybe that's not a real Honda engine. Being I purchased that in 2011, I'm sure Honda won't honor the warranty. So now I need to find a good small engine repair shop that can fix it so I can put it back on the market.

When I Google the problem, it's always the opposite--fuel needle pinned to the left. My case seems unusual.

We've been having constant rain and thunderstorms all month, so the generator got at least weekly and sometimes twice weekly use and I hit the 100 hour mark this week and did the oil change. New Wix filter and Shell Rotella Diesel synthetic oil, per recommendations I found elsewhere on the forum. I unscrewed the plug and opened the valve down below. Expected it to pour out like a faucet, but instead, it slowly dribbled out. Took over an hour to drain. Would have taken two hours, but that I found that if I remove the old oil filter and dead crank it a few seconds, another quart would come out very rapidly from the oil filter port. I got two quarts out that way. But wondering why draining oil from these units is so slow? Instead of going into the pan I put under the outlet, it ran down the rails and inside the unit, making a mess that took me 20 minutes to clean up with a lot of paper towels. Hoping I can find a way to improve the flow so it's not so messy next oil change.

Other than the fuel gauge issue, the generator has been putting in yeoman service. And it's a good thing I got it just in time. My Northstar generator, which has been up for sale for 10 months (Honda V-twin engine with 303 hours on the clock) blew a piston ring today while I was running it to maintain it from taking on moisture. Engine sticker says "made in China" so maybe that's not a real Honda engine. Being I purchased that in 2011, I'm sure Honda won't honor the warranty. So now I need to find a good small engine repair shop that can fix it so I can put it back on the market.