DanMartin

New member

- 1,276

- 17

- 0

- Location

- Hillsboro, Oregon (USA)

I'm totally facinated by this thread. I know next-to-nothing about the engine in question (other than what is in this thread), but let me humbly offer this:

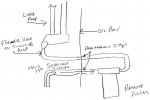

Maybe a dry-sump system? Plenty of off-the-shelf belt-driven pumps out there complete with air separators and multi-stage pump mechanisms. Just block off the existing pump and shaft, plumb in an intake into the pan somewhere, and plumb the externally-driven pump into where the old pump's high-pressure oil went. You can that high-pressure oil through a good filter before it goes to the engine (like a modern engine)...just make sure it's got a pressure bypass for those cold starts (or run a really good low-weight synthetic oil).

You can also hook up an pressure alarm on the pump or a switch to ensure that ignition is cut if the pump fails (or belt breaks or something). This is pretty typical on any modern engine (lose oil pressure and the fuel pump turns off usually, except when cranking or shortly after).

A touch of modern tech can keep that old motor going for years-n-years for minimal effort IMO. Anyways...something to consider.

Maybe a dry-sump system? Plenty of off-the-shelf belt-driven pumps out there complete with air separators and multi-stage pump mechanisms. Just block off the existing pump and shaft, plumb in an intake into the pan somewhere, and plumb the externally-driven pump into where the old pump's high-pressure oil went. You can that high-pressure oil through a good filter before it goes to the engine (like a modern engine)...just make sure it's got a pressure bypass for those cold starts (or run a really good low-weight synthetic oil).

You can also hook up an pressure alarm on the pump or a switch to ensure that ignition is cut if the pump fails (or belt breaks or something). This is pretty typical on any modern engine (lose oil pressure and the fuel pump turns off usually, except when cranking or shortly after).

A touch of modern tech can keep that old motor going for years-n-years for minimal effort IMO. Anyways...something to consider.