- 10,349

- 94

- 48

- Location

- Meadows of Dan, Virginia

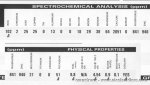

Received the oil analysis reports today.

They more or less confirm my suspicions that the chemical content of the oil is not altered much by filtration.

Lead, Iron, Copper and Silicon actually went up, but that may be due to how the samples were taken, while Aluminum was reduced.

Both samples also contain water (1.7 and 0.9%), coolant and fuel. Fuel was 8.9 and 9.8 % by volume, before and after filtration respectively.

For some reason the viscosity was cut in half in the process, from 9.58 to 4.54 CSt (centistokes)....why would the viscosity change that much by filtration?

....Called the lab on this and the tech said that with that much water, the viscosity can't be measured accurately. Fresh oil off-the-shelf will have less than 0.01% water.......

I'm having computer problems and the scanner is not on line at the moment, but as soon as possible, I'll post the results....

They more or less confirm my suspicions that the chemical content of the oil is not altered much by filtration.

Lead, Iron, Copper and Silicon actually went up, but that may be due to how the samples were taken, while Aluminum was reduced.

Both samples also contain water (1.7 and 0.9%), coolant and fuel. Fuel was 8.9 and 9.8 % by volume, before and after filtration respectively.

For some reason the viscosity was cut in half in the process, from 9.58 to 4.54 CSt (centistokes)....why would the viscosity change that much by filtration?

....Called the lab on this and the tech said that with that much water, the viscosity can't be measured accurately. Fresh oil off-the-shelf will have less than 0.01% water.......

I'm having computer problems and the scanner is not on line at the moment, but as soon as possible, I'll post the results....