Since you expressed a desire to both collect heat from the engine and to apply heat to the engine from the habitat heating system, you will need a circulating pump, so for this application I would not necessarily plumb it from a hi port to a low/suction port. There is a port on the passenger side of the engine near the back of the block I would plumb from the thermostat housing like every other loop draws from, but I would return coolant to that port on the block. Since they are both on the high side of the pressure dividing line between pump and thermostat line, there would be no flow when the engine is running and they would not effect operation of the engine.

i had once thought of using hydronic heating(have it in my home and love it), but the limited floor space(radiating surface) does not make it as practical. It also does nothing for moisture/humidity control(human activities create a lot of moisture), so since I still need to deal with that I opted to keep it simpler with only air heating and on demand water heating. I will provide engine heating a different way… But I did design a hydronic system with two way engine heating…

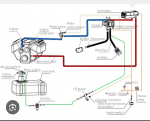

The system was designed around a insulated 2 loop calorifier hot fresh water storage tank. It uses two thermostats and a couple of thermal switches for safety and control.

Domestic hot water heating is the core of the system. The first thermostat monitors tank temp and controls the boiler to maintain that temp(125F), cycling boiler and pump as needed. There are 2 thermal snap switches that will disable the heat source if the tank gets overheated. The flow out of the boiler passes thru 2 heat exchangers to reach the tank. this is all your domestic freshwater. As you draw hot water from the tank the water supply system replaces it from storage and the thermostat fires the boiler as necessary to maintain set temp like any other domestic HW system.

The second thermostat controls your habitat heat. When it calls for heat it turns on the heat system circ pump. This pushes fluid thru the loop in the HW tank collecting heat from there, and on thru a heat exchanger, then on to the heater fan/coil unit or hydronic floor loop to deliver heat to the room. When the tank temp drops, the 1st thermostat calls the boiler and sends heat Into the tank. The heat exchanger picks this heat off first and sends it to the room until the 2nd thermostat is satisfied with room heat and shuts off its pump. When the tank warms enough, the 1st thermostat shuts off the boiler…

A thermal switch on the engine shifts the control of the 1st thermostat from boiler and pump, to just the boiler pump and the engine loop pump. So if the engine is warmer than say 120F if the tank thermostat calls for heat, the boiler pump and engine pump will engage, engine heat will arrive at the first heatex and be transferred into the tank. Again the two thermal switches on the tank will disable the boiler pump and engine pump if the thermostat should stick and the tank become overheated. When the tank is at set temp the thermostat shuts off the pumps. If you have room heat turned on when the 2nd thermostat calls for heat it works the same way except the 1st thermostat will call on the engine for heat if it is over 120F… When you shutdown and the engine cools below 120F, the system will automatically revert to boiler mode.

Engine pre-heating works exactly the same as habitat heating. You turn on a switch which energizes the engine pump. It pushes water thru the tank loop to absorb heat then thru a heat exchanger and on to the engine Warming the block and head. As the tank temp drops the 1st thermostat calls on the boiler which pushes heat thru that heat exchanger so the engine, like the habitat heat, gets first crack at the good stuff out of the boiler… you could put a thermostat on it, or a simple timer, or disable that manual control when you turn on the vehicle ignition, however you see fit.

the core is your fresh water system, both loops for habitat heat and engine heat would be a glycol solution. The drawing does not show any expansion tanks for dealing with thermal expansion so that is also needed…

FYI