cobra5

Active member

- 219

- 194

- 43

- Location

- Stevensville, Montana

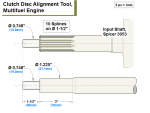

Well I'm finally getting around to getting this done but the credit has to go to my 20 yr. old son who is all over it. He started prepping the job on Sunday and when I got home from work yesterday there was a transmission on the shop floor. I went inside to change clothes and he had already removed the pressure plate, clutch and flywheel. I wish I had his energy. So now I have a question, what clutch type is the correct one to install? I have the five finger plate which to me is odd looking but I see kits available that look like a normal disk type. Ok and since everyone likes to look at photos, I have a few for you guys. This is an Air Force truck that had a little more than 5,500 miles on it so I think the rear main dried out due to lack of use. Anyway, I'm going to replace the clutch disk and either have the pressure plate and flywheel resurfaced or just leave it alone. I know that's normally a big no no but, with so few miles, little wear, and the fact that I don't really drive that often I can't justify the added expense. Anyway enjoy the photos and let the questions/concerns begin.

Clutch

Pressure Plate

Flywheel

Transmission Front

Transmission on Jack

Flywheel Before Removing

Clutch

Pressure Plate

Flywheel

Transmission Front

Transmission on Jack

Flywheel Before Removing

Attachments

-

60.4 KB Views: 48

-

58.9 KB Views: 50

-

42.7 KB Views: 48

-

76.4 KB Views: 45

-

69 KB Views: 46

-

60.3 KB Views: 52

Last edited by a moderator: